Nhà máy sản xuất, Gỗ Phíp tấm , cách điện – Germany

Production plant, Wood chipboard, insulation - Germany

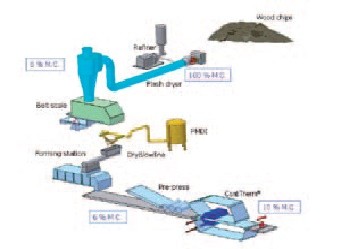

Equipment for insulating panels made of wood fiber

In order to produce fiberglass insulating panels used to resist heat, cold, and noise, Siempelkamp has developed a special manufacturing method. The dry production process allows the production of wood panels from 20 in (0.8 in) to 300 in (12 in).

Siempelkamp presses also enable the production of flexible fiberglass insulation panels used as insulation between the balustrade. A processing system, tuned for the product, completes our package. This processing system includes sawing lines and cut saws, shaped lines, overlapping lines, loaders and unloaders, as well as packaging lines.

Specifications:

Panel production has a thickness of 20 to 300 mm

Energy savings of about 30% / ton compared to conventional wet production

The density can be adjusted from 80 - 200 kg / m³

board length can be adjusted

Adjust the maximum board width to approximately 2,400 to 2,600 mm

The output is 36 - 72 m³ / h

complete, system specific product processing

Customer benefits:

Reduce costs due to dry production

Optimal adjustment of different application requirements

performance-intensive production

Due to our experience gathered for decades in the field of dealing with wood panels and insulating panels such as sandwich or glass parts and wool stone we can provide our customers a The factory concept is optimized for finishing fiberglass insulating panels - exactly according to individual needs.

Our computer technology has proven to be valuable several times in daily business processes through precision machining and unambiguous availability.

Service:

cross cut

Cutting size in continuous mode or with pad pressure

shaped lines

loading and unloading technology

packing line

Customer benefits:

competent planning

Proven factory technology

advanced processing concept

Complete link production processes

TÀI LIỆU PDF