Vegetable Oil Plant - China

Provide design and equipment and technology

In 1991, based on the important sub-solvent extraction technology of Dr. Qi Kun, the world's first extractor developed by our R & D team. Through our years of development and effort, our technology has grown up as our team has gained rich experience in practice. We have done many turnkey projects for domestic and foreign customers. The capacity of the solvent extraction plant ranges from 1 ton to 200 ton / day.

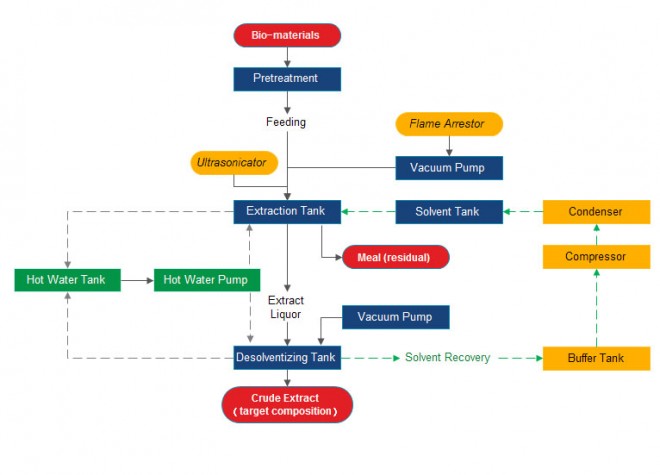

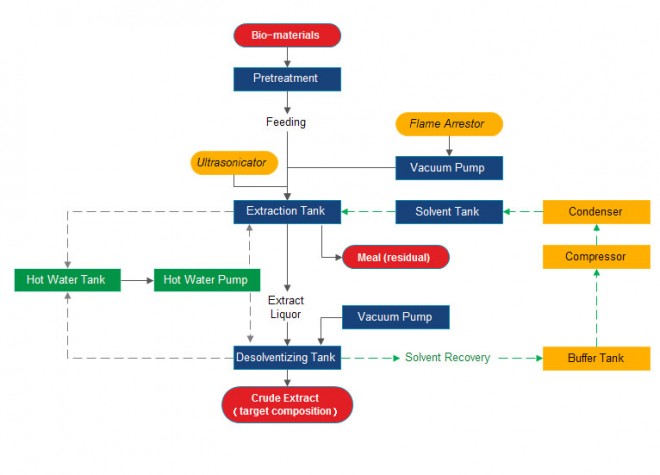

Schematic of Subcritical Extraction Procedure

The production process can be divided into three main parts:

Extract

Open Feed → Elevator → Valve of Extraction → Steam Cup

Wet Meal Drying Section

Extraction tank → Vacuum pump → Compressor → Solvent solvent → Recovery solvent tank

Evaporative oil mixture

Crude oil → Steam → Vacuum pumps → Air compressors → Solvent solvents → Solvent recovery tank

Flow chart of the Complete Solvent Extract Project

Capacity range: 1 ~ 200 T / D

Main application of Solvent Extraction Plant

The complete solvent production line we provide can handle a variety of materials to extract active ingredients such as oils, pigments, oleoresins, proteins.

Precious Vegetable Oil: Wheat germ oil, grape seed oil, seed oil, and so on

Natural pigments: chili pigment, yellow continental pigment and so on

Vegetable Protein: Disintegrated peanut oil, soybean meal, bleached protein powder, and so on.

Oil

Animal oils: horse oil, ass oil, crocodile oil, and so on

Micro algae oil, microbial oil, insect oil and so on

Oil Filter

Successful solvent extraction projects

Extraction equipment has been used in various industries for nearly 30 years in China, such as biomedical industry, biotechnology, food industry and oil processing industry. As the international market expansion of this advanced equipment is still in its early stages. Most of our projects are in the country. See the following pictures to see some of these projects. Do not hesitate to contact us if you are interested in finding out more information! You are also welcome to visit our project!

Small Scale Solvent Extraction Plant

Features of our solvent separator

It eliminates the need for heating during distillation compared to conventional solvent extraction. Its most prominent is the normal temperature extraction and thawing of low temperatures, which can protect the heat-sensitive material of the natural material from destruction, and also avoid the risk of oxidation.

It can completely protect the quality of proteins, pigments, pharmaceuticals and essential oils.

Consume less solvent: Solvent to handle one ton of material under 8 kg.

Energy Saving: It can save up to 70% of the heat compared to conventional hexane extraction.

Limited investment, low production costs and large scale production (compared to supercritical fluid extraction)

Technology of solvent penetration at low temperature

Low-temperature biological extraction technology, invented by Dr. Qi Kun, is also feasible for complete solvent separation plants. Low-temperature biological extraction technology refers to solvents, under room temperature and certain pressure conditions, in combination with auxiliary liquids or mixed solutions, which act as solvents. , passes through the digestive tract, evaporates, dissolves, condenses and other processes in the system to extract the target ingredients from the natural material.

Subcritical liquids are usually some chemical compounds that exist in the form of a liquid when its temperature is higher than its boiling point but lower than the critical temperature and its pressure is lower than the reaction pressure.

Our complete solvent extraction plant selects high purity (R600a), tetrafluoroethane (R134a), liquefied petroleum gas (LPG) and other solvents, butane, high purity iso-butane (R600a). When it exists in the form of a sub-liquid, the molecular diffusion capacity becomes stronger and the transport speed is faster, significantly increasing the permeability and solubility of non-polar and weak components. in natural materials. Sub-standard operation will not destroy the thermal sensor. And, the target product extracted is completely green and the environment. This technology is a revolutionary innovation in the field of bio-mining and very promising in the future.

This is purslane oil production line 80 tons / day. This is a turnkey project built in Beijing China. See the words below for more information on Purslane oil extraction.

If you are interested in finding out more about starting a herbal oil or essential oil factory, you can contact us and let us know your needs. Then we can help you make customized business plans depending on your specific needs and your cost budget.

The fatty acid composition of the orange oil

| Axit béo | Công thức phân tử | Nội dung (%)

Purslane Dầu thực vật nguyên chất | Nội dung (%)

Dầu đậu tương hạt giống |

|---|

| Axit myristic | C14: 0 | 0,22 | - |

| Axit palmitic | C16: 0 | 17.06 | 9,88 |

| Axit stearic | C18: 0 | 4,92 | 2,60 |

| Axít oleic | C18: 1 | 10.32 | 1,18 |

| Axit linoleic | C18: 2 | 33,19 | 35,93 |

| Axit Linolenic | C18: 3 | 31,04 | 49046 |

| Axit arachidic | C20: 0 | 0,72 | 0,39 |

| Axit behenic | C21: 0 | - | 0,24 |

Oxit dimetyl axit phthalic | C 14 H 18 O 16 | 1,46 | - |

Camellia Organic Longan Oil Production Line 50TPD

This is 50 tons per day of camellia seed oil production line for Kanglongshan Tea Company, located in China. Contact us now to get detailed project plans and equipment costs ....

20TPD grape separator

This is the project of 20TPD grape seed harvest (20 tons / day) designed and built for Hebei Nongsheng Biotech Company. LTD. It is based on the low temperature mineralization of the mining process

5TPD black pepper extraction plant

This is a black pepper seed oil and flavor extraction line located in Sichuan province, China. The productivity is 5 tons / day. The whole extraction process is carried out under vacuum and low temperature conditions.