Technology & equipment - for plants, internal combustion engines - Austria

Technology & equipment - for plants, engines - Austria

Engine production

AVL is a reliable partner to assist our customers to ensure quality production in the production and production of internal combustion engines. The increasing complexity of internal combustion engines requires an appropriate test and test method and inspection technology that reviews manufacturing and assembly processes related to modern engine technology. .

Internal combustion engine design

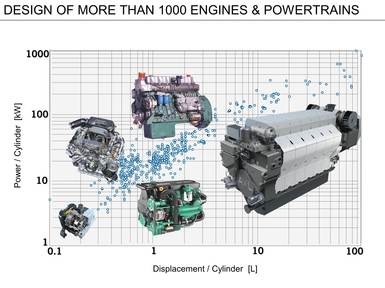

Internal combustion engines (ICE) will be the backbone for vehicle transmission systems even in the near future. But more measures are needed to achieve today's stringent emission standards and continue to increase development goals that can only be achieved with modern technologies, design methods and tools. . The 60's of experience in developing and designing the internal combustion engine of AVL is a growing capital. We have all the skills needed to tackle new challenges under one roof - a strong team of engineers, most modern development equipment and proven processes. In designing IC motors in the shortest time with the highest quality.

Solutions

Develop and design IC engines (diesel, gasoline and alternative fuels) for all power levels, specific spraying and charging technologies.

Expertise for all industries and applications, from motorbikes and passenger cars to large engines for ships or generators.

Extensive research and development activities and extensive project experience to the SOP and beyond

Innovative and reliable solutions for different emission standards (post-treatment systems, catalytic converters ...)

Design processes based on efficient and effective simulation to optimize development time. Future mecha-concept and innovations (eg, miniaturization) from low entry level to high end applications

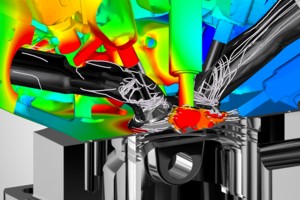

AVL FIRE ™ tool

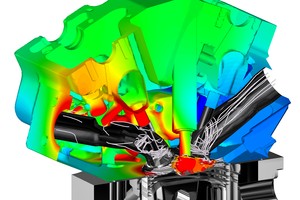

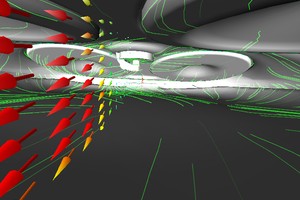

The AVL FIRE ™ Engine is a CFD solution specifically designed to assist in the development and optimization of IC motors and engine components.

Due to its unique modeling features, the AVL FIRE ™ Engine is the CFD solution of choice when analyzing and optimizing fluid-flow tasks related to IC motors, such as flow in taps. spraying, fuel injection, combustion, emission, heat transfer and post-exhaust treatment.

Benefit at a glance

Highly realistic 3D CFD simulation.

Dedicated to address development tasks related to IC motors.

Accurate, valid and proven simulation models.

Robust process automation and design studies support high performance simulation to improve product quality and maturity.

Analyze the results to match the technical tasks.

FIRE ™ simulation tool

Single phase flow

Eulerian and Lagrange multiphase flows

Transport of species and general gas phase reactions

Burning and emitting internal models

Physics and Chemistry in post-treatment systems

Thin film

Line in the foam media

Lines in systems with and without boundaries move

Heat transfer. Radiation

Internal combustion engines for industrial machinery and tractors

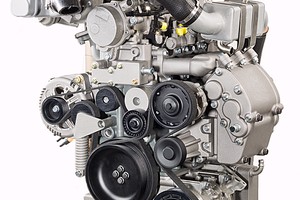

All motors for industrial machinery need to include a huge variety of different applications in terms of design, duty cycle and operating conditions. This requires a dedicated engine architecture as well as high flexibility to adapt the engine to the individual requirements. AVL engages in engine development and powertrain programs with all major industrial machinery manufacturers and supplying industries worldwide. This means AVL has the expertise to provide accurate solutions and advanced technology to our customers. All these experiences show direct advantages in each project of our customers to quickly find the optimal solution that suits each customer's requirements.

AVL Solutions

Development of new motors for industrial machine motors as well as upgrades or minor improvements

Alternative fuel engines develop as gas engines

Activities to improve fuel efficiency

Optimized interaction of the engine in the complete powertrain.

Engine portfolio consultancy

Apply development variants

All technical activities such as design and simulation, calibration, sound engineering to benchmark

While compliance with stringent emission standards worldwide is required, the focus is also on reducing product costs and TCO (total cost of ownership), where the fuel economy is an important factor.

Internal combustion engines will continue to play an important role in future industrial machinery systems. Concepts of alternative fuels such as natural gas engines will become more important for all engines. This is mainly due to favorable fuel prices and a focus on CO2 emissions. AVL has a number of ongoing research and development programs ...

AVL CRUISE ™ M engine

The AVL CRUISE ™ M engine is the focus of a whole range of development solutions based on a multidisciplinary model. It focuses on real-time system-level simulation of the engine that can be used throughout the vehicle development cycle.

Our goal is to support development with an integrated, open and consistent approach that allows the reuse of high quality models. In addition to traditional technical office applications, the AVL CRUISE ™ M Engine also introduces the development and validation of seamless control functions from MiL to SiL to HiL. Modular scalability with scalable, and an integrated open concept enables the re-use of mature, high-performance, mature office models in a system development approach. based on advanced model.

Benefit at a glance

Motor model scalability can vary from replacement agent level.

Cylinder angle resolution and air path solution.

Factory model from concept to calibration and testing.

Open interface for 3rd party standard support tools (FMI).

ECU calibration with virtual engine at initial development stage.

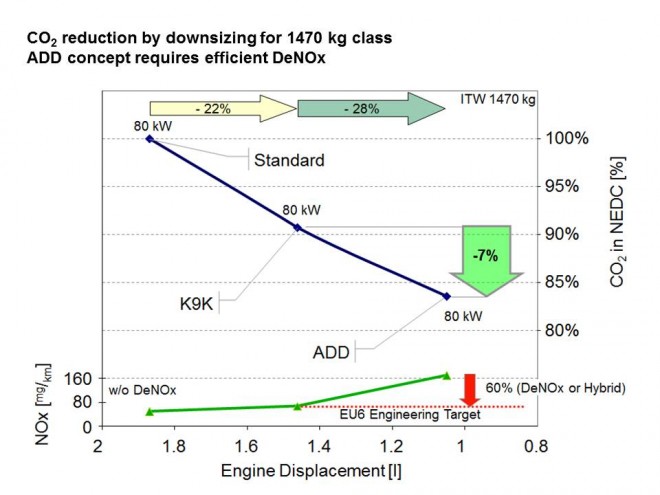

AVL diesel engines dropped sharply

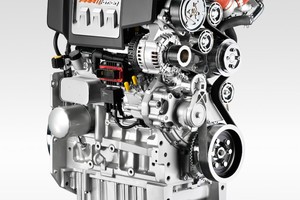

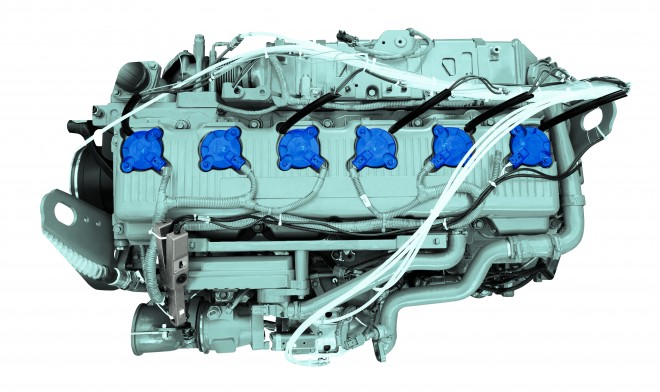

AVL has come up with a concept for a more narrow approach to the next generation of powertrains by reducing the engine further down to 1.0L using a 3 cylinder concept with capacity namely 80 kW / L

Significant CO2 emissions in the NEDC

Ability to reduce 7% depending on vehicle weight and DeNOx strategy

Performance and driving power are similar to the K9K 1.5L

Performance objectives are fulfilled with the design limit of 190 PFP bars

Engine structure is able to withstand high mechanical load and heat

EU compliance 6

Emission of Euro 6 with NOx after treatment

Behavioral NVH is equivalent to K9K 1.5L

There is no balance crane in conjunction with the AVL mounting concept

NVH remains a challenge for 3-cylinder engines in larger cars in view of the torque fluctuations.

VL and Renault are working closely to define a hybrid hybrid concept suitable for EU6 emission limits. Consequences for the design of the basic motors of the narrowing approach have been established by the design study method supported by simulation. The main standards for this engine system are to meet the customer's expectation of performance and control, as well as keeping the NVH in the configuration of a select 3-cylinder engine close to the engine. Standard 4-cylinder engine.

AVL EXCITE ™ NVH Analyzer Engine

AVL EXCITE ™ is the ideal solution for analyzing engine and acoustic vibrations in all stages of engine development.

With simple and rigid body models starting from a single model or 2 models, AVL EXCITE ™ supports NVH analysis of engines and power units in the early stages with the main goal being layout. basic installation.

Detailed model simulation with cranktrain system and rigid body balance, different levels of mounting mode are expanding the frequency and scope of the application is covered, such as regulator look at the mounting positions and characteristics, frame vibration, the effect of the mass balance system.

For motors and motors, high frequency dynamic analysis, dynamic multiple dynamic simulation models are used, FE connection based on solid-state condenser connected through non-linear links. This allows efficient sound analysis of any engine when considering all the internal combustion engine noise mechanisms. The main source of noise in the engine is the space in the cranktrain bearings, pistons to the piston slots and valve contacts and timing systems.

Benefit at a glance

Optimal solution for vibration and task-oriented analysis in various stages of engine development. Reduce experimental effort by simulation based on NVH optimization. Sensitivity analysis of noise design parameters is difficult to reach through experiments

The complete system approach delivers accurate audio noise levels up to 3.5-5 kHz. Automatically compresses the evaluation result of a large amount of audio output data.

Precise boundary condition for vehicle frame stimulation (cabin noise)

The entire analysis work is composed of, from low frequency vibration, high frequency noise-resistant structure evaluated to calculate sound radiation

Function

Basic unit layout tool

Different levels of motor-mounted models (frequency and amplitude dependent)

Measurement based on engine settings

Optimized models for predicting non-linear physical behavior in contacts (bearings, valve valves, timing drives, piston-liner contacts)

Evaluate the contribution of the body to the level of local vibration through model contribution factors (MCF)

Automatic processing after 2D and 3D sound processing (constant surface level, integrated values of selected areas / components, etc.)

Effective calculation of sound radiation using Wave Based Technology. Communicate with all conventional FE solvers, optimization tools, MATLAB ® / Simulink ®.

Internal combustion engines for commercial on-road power lines

With more than 60 years of experience in engine development with a particular focus on developing engines for commercial vehicles, AVL is a suitable partner for all development activities creating a new engine, upgrading or improve. AVL has developed unique tools for the development of engines in the complete Powertrain to optimize the interaction between different powertrain systems.

The development of new engines for engines

On-road as well as minor upgrades or enhancements

Alternative fuel engines develop as gas engines

Activities to improve fuel efficiency

Optimized interaction of the engine in the complete powertrain.

Engine portfolio consultancy

Apply development variations. All engineering activities like design and simulation, calibration, sound engineering to benchmarking.

To analyze the Dedicated Application and its variants by means of system engineering to truly adapt to the ultimate technical solution to the engine development. AVL's own tools such as AVL Cruise ensure accurate and professional analysis of the surroundings to the engine (car, driving cycle, etc.)

Unique AVL tool chain features include intelligent simulation applications covering all areas required to ensure an efficient development process.

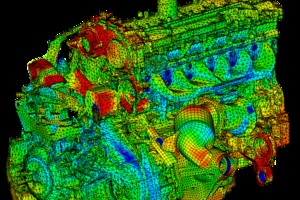

AVL EXCITE ™ Engine Durability and Stability Analysis

AVL EXCITE ™ is the perfect solution for the dynamics, durability and durability analysis of engine parts, valve motors and timing motors and tribological investigations of lubricant motor contacts. burn in.

AVL EXCITE ™ is a proven tool for all engines, from small cylinder engines to large diesel engines. Different model levels for individual components, as well as for the whole system, support optimal model depth for each stage of engine development, from concept to layout and stage. final design.

Powertrain analysis of specific workflows, automated modeling and performance evaluation capabilities help engineers achieve shorter project duration. Pre-engineered tools such as AutoSHAFT for automatic crankshaft modeling,

Benefit at a glance

Optimal solution for all stages of development, engine size and configuration

User-oriented engine and operating system oriented for efficient modeling and performance evaluation

Accurate dynamic load calculation and deformation for strength and durability support design development closer to the strength limit.

The level of detail of nonlinear linear connectors to hydrodynamic contact models

The entire workflow is comprised of an integrated Abaqus ® FE-solver solution and a fe-safe TM fatigue analysis tool.

Automatic emission control engine

AVL iGEM Engine / GEM301 EC

The iGEM Engine AVL Series offers an application package for automatic emission control on engine chambers.

AVL iGEM Engine is used for certification, research and development, or for the appropriateness of production purposes. Based on the established success of the AVL PUMA Open, AVL iGEM Engine delivers high scalability. The simple parameter allows for adaptation to a combination of different test configurations and client application needs. It offers the highest level of flexibility and customization for the user. In addition, the AVL GEM301 EC adds AVL application solutions with flexible configuration for R & D testing.

Benefit at a glance

IGEM Tool: Observe EPA 1066, GTR-15, Euro 6d, China 6

iGEM Engine: Fully automated procedures for all devices (eg calibration)

IGEM tool: independent of model, model and equipment supplier

GEM301 EC: The perfect base for R & D development

GEM301 EC: Simple operation using PUMA tools and windows

Market Requirements

International emissions laws are constantly changing, as do engine design methods and measurement methods. Manufacturers and suppliers also need to adapt to these constantly changing requirements. This promotes the need for innovative solutions in the automation of emission tests. AVL iGEM Engine and AVL GEM301 EC provide high levels of tuning for different test configurations and different user needs - enabling users to be in control of a challenging market.

Drive system design for passenger cars

Reduced CO 2 emissions and fuel consumption, optimal steering and maximum safety are major drivers for the design of modern passenger car systems - increase for manufacturers to reduce development and production costs as well as market time.

The design is at the heart of the new drive system development, integrating the frequent conflicting requirements to provide a total solution and documentation for that solution for mass production duplication.

AVL understands and processes the complexity of modern electro mechanics and all its elements. For us, motors, post-discharge, transmission, electrical, electronic and safety - including the corresponding control systems and software - are the best tuned components of a solution. integrated.

Customer benefits

Relying on AVL's expertise is the best solution to gaining technical advantage:

The multidisciplinary team has diverse experience for development projects based on the needs and specific needs of our clients. Including all aspects of the specific drive system under one roof (design, simulation, development, research, plant and production engineering). Experience with all types of powertrains traditionally. Experience with all types of hybridization including battery design

Detailed and proven concepts with accurate prediction of fuel consumption, emissions, steering, reliability and functionality.

From the first concept to the design for testing and production

Use standard databases and measurement data to analyze trends and goals. Simulation decision support for all relevant areas.

Use coordination effects with other development areas, for example to simulate energy management

Solutions

Define and evaluate concepts for all elements of the passenger car system in close cooperation with customers. Effective design processes are based on a "front-loading" simulation approach

Understand and experience the most recent requirements for ICs on shrinkage, post-discharge, electrification and hybridization. The only systemic claim of all modern transmissions ( Powershift, DCT, CVT) .Design-oriented solutions manufactured according to customer requirements and product cost

AVL FIRE ™ burners and burners

The AVL FIRE ™ combustion and emission model allows the calculation of transport and mixing phenomena and simulates combustion, combustion and emissions in internal combustion engines and other combustion equipment under conditions premixed, partially premixed and / or not mixed.

Liquid thermodynamic simulation software

AVL FIRE ™ is the leading CFD simulation tool in the field of combustion analysis. It specializes in the precise prediction of all processes involving IC motors including spray injection, fuel injection, combustion, exhaust gas and exhaust after treatment. The software also supports the development of power systems and power lines.

Calibration

Modern electromechanical development creates significant challenges for the automotive industry. The essential attributes of the car - performance, driving force, fuel consumption, emissions and acoustics - depend on the optimal adjustment of the control unit. On the one hand, these calibration jobs are becoming more complex but on the other hand, require optimal results in a shorter time. To cover much of the daily work, calibration engineers need to

An effective tool for bringing new methods into practice.

Stable results in solving all calibration tasks require modern software tools to meet the complexity of tasks and applications. In the process of using them in the development process, these tools must meet requirements such as data quality, reproducibility, stability and safety.

The desired effect and necessity of the calibration work process require the permanent derivation of the method. AVL has long-standing experience and is a leader in developing high performance tools and methods in XCU calibration. Our goal is to provide a complete workflow for each single calibration task. A significant increase in performance when using AVL calibration software has been demonstrated

t