Starch Processing Factory - Denmark

Supply, equipment, production line and technology transfer

SiccaDania is a specialist in the design,

Fabrication and construction of variable starch factories.

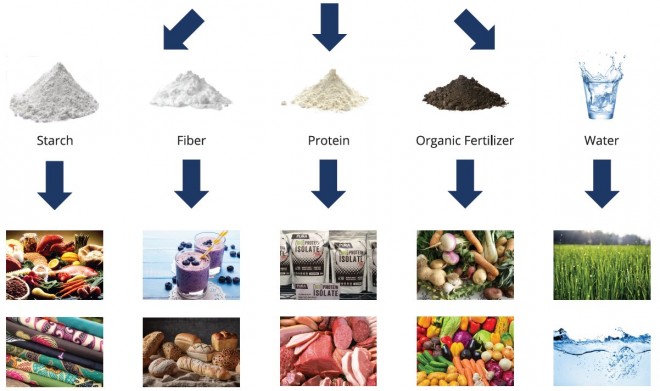

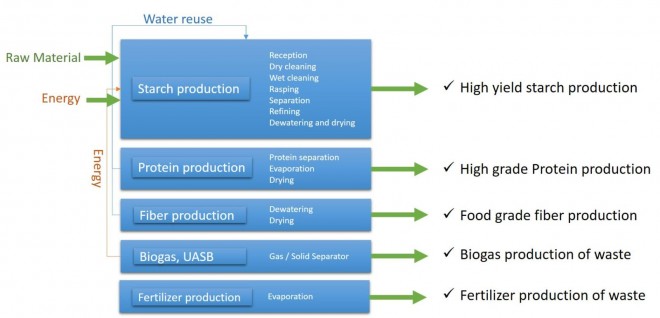

The technology of the company was developed to produce:

Starch yield as high as possible.

The highest quality starch can be used in a certified industrial process.

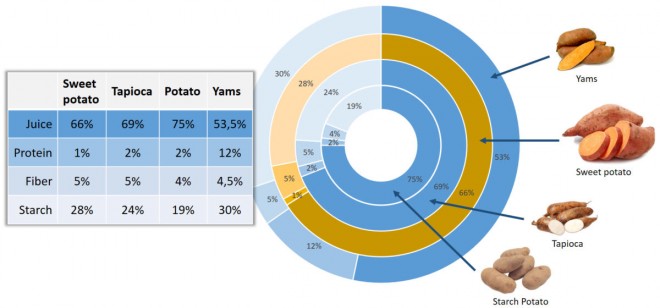

High value added products. By-products such as protein and fiber can account for up to 70% of net profit.

Low energy consumption.

Circulation of waste water and reuse of waste to produce fertilizers or biogas.

Starch carrots

Rasping is the first step of starch extraction. The purpose is to open the tuber cells and release the starch. The resulting mud can be considered as a mixture of pump (cell wall), juice and starch. With modern high-speed assembly machines, hitting is a one-time operation. SiccaDania offers high efficiency SiccaDania Rasper.

Clean-Flow

The efficiency of potato washing before further processing increases productivity and significantly reduces maintenance time and costs. Any soil or soil that is not removed during the washing stage becomes a source of problems during processing. The Clean-Flow process is an in-situ wash system that uses fresh water through the nozzles in the final step. Potatoes are evaporated by water and pass a rock trap at the entrance to the wash station. These stone traps use the difference in density between the rock and the potato, where the upstream stream carries potatoes through rock traps. Here the stone is removed and collected on a conveyor belt. The water level in the laundry basket should be kept low to prevent the potato from floating. Besides the transport, the drum also ensures that the potatoes rub strongly against each other, thus effectively removing fungus, stains, skin and dirt from the surface. Floatation water can be recycled after filtration through the sand.

Achieving high purification standards improves starch refining significantly and is one of the most important steps to be taken when improving the overall profitability of a plant. SiccaDania offers a unique CleanFlow washing machine to meet this economic need

Starch Factory

SiccaDania mainly focuses on the potato starch and cassava starch industries. The ambition is to expand existing technology solutions that allow starch producers to become more profitable by unlocking the potential for profitability in potato by-products or cassava processing. Complete solutions are provided for proteins (both food and human), and fiber as well as converting wastewater into beneficial fertilizer. Complete solutions also apply to the selected starch production areas.

Key people in Sicily are tools to assist European starch producers to grow their activity from low-yielding to high-yielding producers with extremely low returns. number. It is important to turn low-value byproducts into high-value products. In SiccaDania we consider ourselves to be a technology leader in this field.