Seafood processing factory - Germany

Providing equipment and technology of - Germany

Processing aquatic food

Your partner in the seafood feed industry. ANDRITZ designs and manufactures all major processing machines and provides complete feed solutions for the global seafood industry.

Our extrusion technology is based on a competitive approach to meet the requirements of successful aquaculture feed manufacturers and aquaculture companies.

ANDRITZ equipment for aquaculture feed production

Our seafood feed processing technology is available in different models and with optional accessories to provide optimal solution for your specific production needs.

Milling machine

Andritz's feed and fuel technology provides high-performance hammers to reduce the optimal size of raw materials.

Decades of experience and highly qualified product experts make us a strong partner in providing hammer mill to reduce size. The range of ANDRITZ mills includes the need for an extremely fine or coarse crusher with high capacity.

Air and dust filters

ANDRITZ provides a product-based solution for vacuuming and filtering industrial dust for many industries. ANDRITZ filters ensure reliability, efficiency and flexibility.

ANDRITZ has more than 30 years of experience in filtration and dust treatment and our filters have proven their superior functionality and operational reliability in many industries. The result of the partnership is targeted to customers, suppliers and academics as a range of filters that can be used for most types of industrial dust filters. Our filters are a safe choice for dust filtration at your manufacturing plant.

Weighing system

ANDRITZ offers a range of weighing systems for use in various steps in the food production process.

Our weighing system is, among other things, suitable for the weight of raw materials and micro and macro weights.

ANDRITZ mixer for optimal mixing of food ingredients

ANDRITZ offers a wide range of high quality mixers for all food applications, ensuring that all components are mixed to ensure consistent feed quality. Ensure distribution of nutrients, vitamins and minerals uniformly, resulting in uniform nutrient content in each pellet. Andritz's mixers offer solutions for both cake and ribbon mixing

Extruders for aquaculture feed

When producing aquaculture feeds, it is important to consider feed characteristics for fish and shellfish. ANDRITZ provides extruded, high-capacity extrusion lines for the production of fish and fish meal. ANDRITZ extruders ensure that food has the right physical properties - give accurate submerged properties in the water where the food needs to be approached.

Combi dryers

ANDRITZ mixer is specially designed to produce high quality aquaculture feed and pet food. It ensures a smooth, even, and efficient drying of the extruded food particles.

With individual temperature control and air in each area, the diffuser dryer ensures optimum drying. It covers a range of production capacity up to 30 tph and product sizes ranging from 0.8-40mm.

Air conditional

ANDRITZ offers four different types of air conditioners to ensure the best preparation of materials before pressing or pressing.

Proper adjustment of the material is necessary to obtain a good quality tablet and effectively use the installation or extrusion. Optimal conditions allow the activation of natural binders using heat, humidity and time. ANDRITZ conditioners include single or dual conditions.

Cool

ANDRITZ flow cooling solutions ensure the correct temperature of the tablet before storage. The vertical coolers are suitable for optimal cooling of extruded products or tablets based on applications and preferences. customer. It prepares the tablet for optimal storage and is one of the cleanest solutions due to its flush system

Vacuums

The ANDRITZ vacuum control system provides precise control of vacuum pressure, liquid addition and cycle time to allow for flexibility and repeatability of absorption and penetration.

Extruded tablets have a very porous internal structure. It lies in the holes of this internal structure that add liquid to be retained. The goal of vacuum coating is to use a different pressure to squeeze liquid through the outer layer and deep into the foamed area of the tablet.

Bags loaded

Hammer mill is an important component in most food production activities. Its performance and reliability can only be optimized if it receives a consistent, consistent supply of material across the suction area of the hammer mill. It also requires a Automatic control system automatically adjusts the speed of the feeder to control the speed of fast food and accuracy according to the optimal performance of the crusher.

Automatic system for processing aquatic food

ANDRITZ has extensive experience in controlling the automation of aquaculture feed production. We can guarantee a reliable and optimized solution for your entire production process.

By maintaining close communication with our valued customers and with ANDRITZ's internal mechanical engineers and processes, we continually set new standards for performance and functionality. Art of Automation Solutions. Our focus on innovation makes us the market leader in process automation. We set the trend, not just follow them.

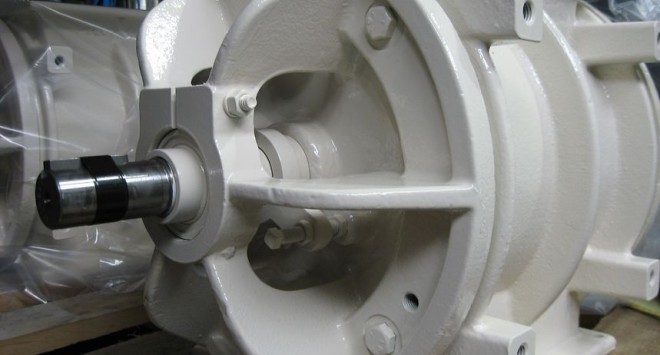

turn valve

The ANDRITZ valve of Sprout's exhaust valve is rugged and has no trouble. They are ideal for use as air feeders and locks for vacuum and low pressure systems.

Rotary valves help your compressed air system achieve maximum efficiency. Accurately-crafted to maintain properly sealed air, our rotary valves are rugged and reliable, even if you are shipping abrasives and corrosives. Available in many models, sizes and construction materials, the ANDRITZ rotary valve is the most versatile component in the transportation and transportation of diluted compressed air.

Separation of air density

ANDRITZ is designed to separate heavier density materials such as rocks and mud from the grinding line of material into the hammer mill. Air conduction material through the separator. When the material is transported through the openings, heavier materials fall into the trap under the weight of gravity. Light materials are transported through the opening and into the saw below. An inside magnet is also available to remove metal trap iron from the product line.

Fodder machine

Using ANDRITZ's feeding cabinets will help ensure that you have cleaned and replaced dry food and soft food ingredients. This compact device removes metals and other foreign materials and ensures no-block food. The same effect when used after grinding and mixing or in front of the rubbing machine. High capacity, low operating costs, minimal service and energy requirements, dust-free performance and flexibility mean that this filter is designed for simplicity and functionality. Animal feed washer is available in four models. The largest model has capacity of up to 150 tons per hour while the minimum modeling capacity is 30 tons per hour. All energy projections are based on a 1/2 open bore and 30 lb / ft3 material

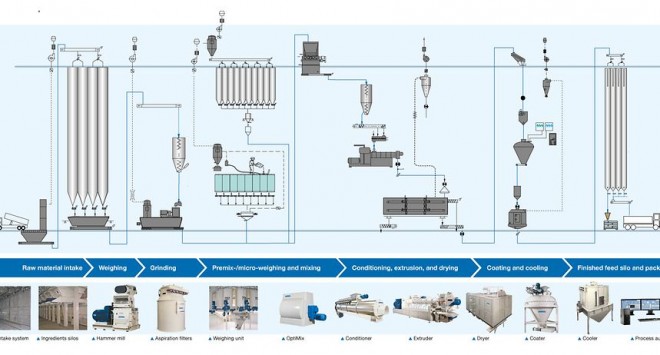

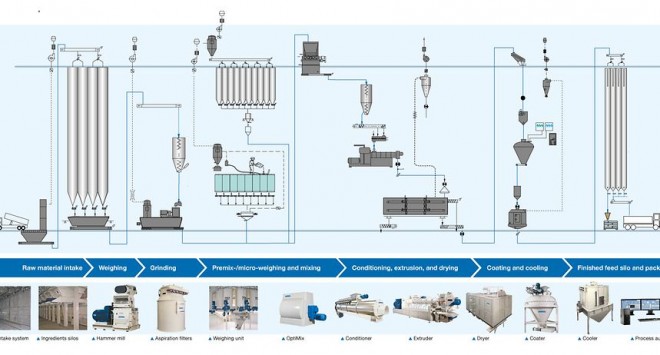

From raw materials to finished pellets

ANDRITZ is one of the few companies capable of designing, manufacturing and supplying each major processing machine in the food production line, as well as designing and manufacturing the entire production line. Wherever there is your food packaging plant and whether you produce pelleted feed for poultry, pigs, cattle, etc., we provide a full range of machinery and equipment from raw materials. whether to finish the food.

Factory design and design solutions

ANDRITZ is the perfect partner for the design, engineering, supply, and construction of your seafood feed mill. Your request is our encouragement, and our project and process engineers have the skills to identify the best fish feed solution. They work closely with you to select the most suitable elements from a variety of key processes, with custom solutions for nonstandard requirements. Experts and process specialists are part of the process of developing your project right from the start, ensuring high quality, high performance, cost-effectiveness and reliability.