Nhận tổng thầu EPC-NM Nhiệt điện 100 MGAW/h-Austria

Received the EPC-thermal contractor 100 MGAW / h-Austria

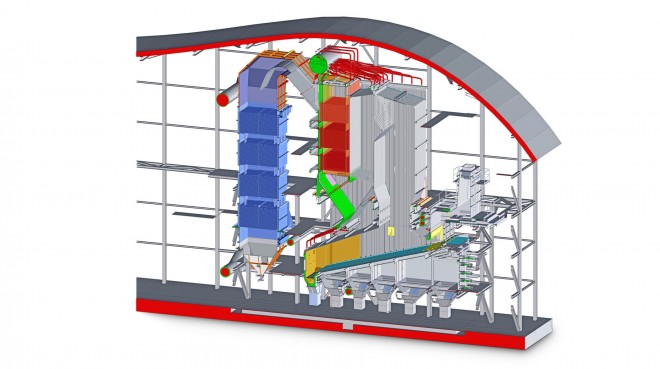

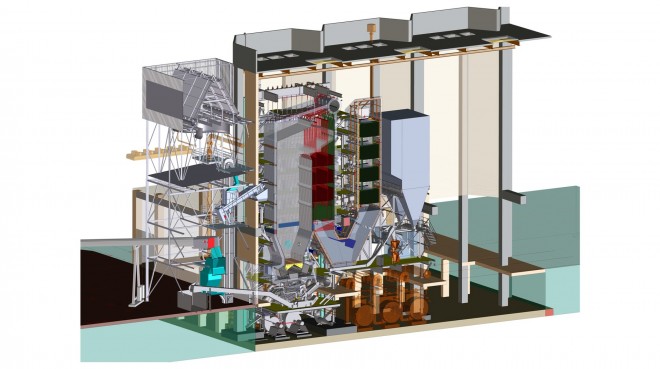

Solid fuel burning plant

(Fireplaces and tubs)

Use of burning technology and precision boiler technology for fuel.

BERTSCHenergy offers customized solutions for a wide range of solid fuels. The choice of combustion technology depends on fuel consumption parameters and design parameters such as emission limits, load change rates and availability requirements.

Parameter

Heat - Approximately 15 to 100 MWth

Air volume - approximately 15 to 100 t / h per unit

Vapor pressure - approx. 40 to 130 bar

Steam temperature - up to 540 ° C

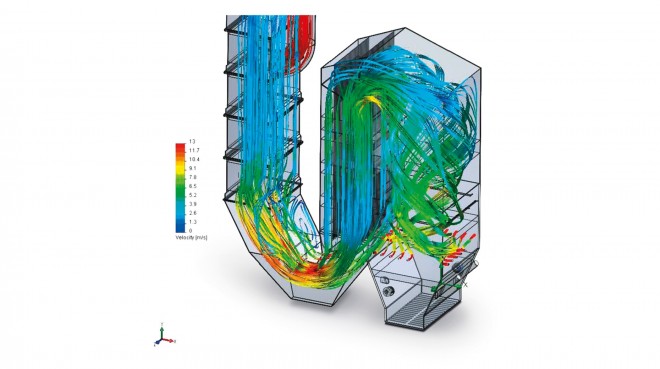

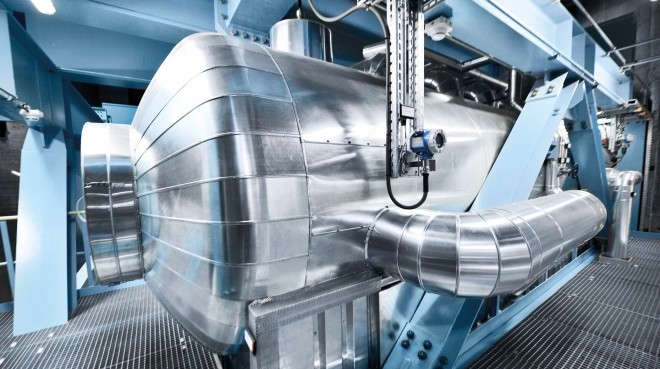

BERTSCHenergy provides hot water and water-cooled air cooling, integrated into boiler water pipes. The combustion process is optimized by means of aeration and spray circulation.

CAPACITY FOR FUEL SIZE UP TO 700 MM

Unprocessed biomass such as waste wood, wood chips, landscape materials, bark, sawdust. Wood from rotational plantations.

Fluidized boilers show technological advances for boilers. The decisive advantages are greater flexibility in fuel parameters (eg value-added ice) and lower emissions. The built-in boiler bed is equipped with an open hollow hole to remove coarse particles such as stone and ceramics. The sand sands are deposited by a mixture of combustion air and circulating air.

QUALITY BOTTLE SALES FOR UPGRADE UP TO 250

Biological residues (wood, waste wood, sawdust, pig manure / poultry manure and other agricultural waste). Waste (waste, mud)

For the most efficient use, BERTSCHenergy monopoly pursuit of customer-oriented solutions. Therefore, high pressure power plants employ kiln technology and boilers that are precisely tuned to existing fuels and customer requirements.

Natural circulation boilers as a membrane structure with post combustion chamber and downstream radiation and circulation rings. Economizer as a free metal sheet construction.

Controlling the temperature of superheated steam by means of a cooler or a tank cooler. Boiler cleaning system such as vacuum, water cannabis, shower sanitizer. Optional use of a condenser unit. furnace for maximum heat recovery from furnace gas

Apply appropriate exhaust fumes, in accordance with the corresponding emission limit values. It consists of the following components or combinations thereof: SNCR-systems for reducing nitrogen oxides.

Electrostatic separator (ESP) with or without front separator. Cloth filter with optional dehumidifier to reduce HCl and SO2 emissions as well as heavy-duty bonding metals.