Nhà mây chế biến trái cây và rau quả - Hoa Kỳ

Rattan and Fruits Processing - United States

Processing fruits and vegetables

Best, cleanest in your package.

Bühler provides advanced processing solutions for the fruit and vegetable industry - from optical sorting of frozen to dried products, roasting and packaging equipment, our wide range is suitable to meet any Designed to easily integrate into existing product lines, our range of processing equipment provides the processor with a degree of additional assurance; Reliable performance for end product quality, product design designed to withstand harsh processing environments and advanced technology to ensure the safest, cleanest product in your package.

Equipment and solutions.

Bühler is a leading provider of optical classification solutions for food and non-food processing industries and has been at the forefront of pioneering optical classification technology since 1947. With significant investment commitments In research and development, Bühler's proprietary classification technology delivers excellent results in removing the most challenging defects and foreign materials in a wide range of applications.

Processors of fresh and frozen vegetables may be the secret of the online classroom

Performance when placing Bühler optical classifiers in their processing

line before blanching, after blanching, after IQF or in packaging

row.

Main benefits

■ The most hygienic photo classification machine,

reduce the risk of contamination

■ Unforeseen errors and overseas

material detection

■ Top class classification

technology

Main and minor color defects such as white, green and dark as well

as foreign materials including stone, insect, mouse, plastic, wood, glass and

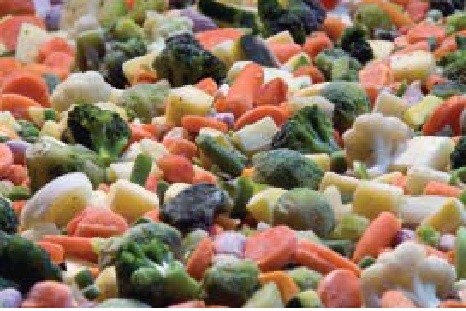

Cardboard can be moved from many different types of fresh and frozen carrot applications. All sorts of color defects ranging from yellow, blonde, khaki and nightshades are easily removed using Bühler's advanced color and custom camera. Foreign Materials and Unrelated Vegetable Material (EVM)

Snakes, rods, insects, snails, dragons, mice, snakes, forests, plastics, glass and stones can be removed without any sorter adjustment.

Typical defects are eliminated including: packaging materials such as wood, cardboard and plastics as well as bypassing EVM so that processors can be confi dent of top quality products before packaging.

Defects such as white, pink, blue, moldy or soft cheese, as well as foreign materials including insects, snails, trunks, trunks, glass andresins are eliminated with high efficiency without compromising. to value, fragile product.

Prior to blanching, SORTEX® sorters were used to remove color defects, extraneous plant matter (EVM) and foreign material optical to save processing resources further down the product line. higher can be achieved.

Common color defects can be enhanced during blanching and SORTEX® sorters are well equipped to ensure that any remaining products are evenly removed. A robust classification solution before freezing, including before blanching and after blanching, is essential to reducing the risk of bacterial contamination.

In the frozen state, the SORTEX® sorting machine is equipped with technology to remove subtle color defects as well as any remaining shape malformation. They are also perfectly suited for batch cleaning processes for the elimination of EVM, offshore materials (FM) and FM packaging.

At the end of the process, there is a risk of FM packaging such as wood, plastic and cardboard

import product line. SORTEX® sorting machines are optimized for detecting a wide range of foreign materials in just one simple setting to ensure top quality products are safe when the intake is reached.

The SORTEX® K range uses a cutting edge, two-sided detection system to remove the most challenging defects in canning or fresh applications. High-performance sorter can inspect the product in one batch and can be equipped with PROfi le ™ technology for EVM's outstanding detection to eliminate the risk of foreign material. SORTEX® K is also hygienic, stainless

Steel frame with IP56 protection.

■ 12.1 inch user-friendly touch screen interface

■ Customizable color camera

Display width 1200mm

■ PROfi le ™ technology

■ 256 high speed, high speed sprayers

■ PowerslideTM conveyors

■ Preset modes

■ External USB port for data recovery

■ ProSortXTM operating software

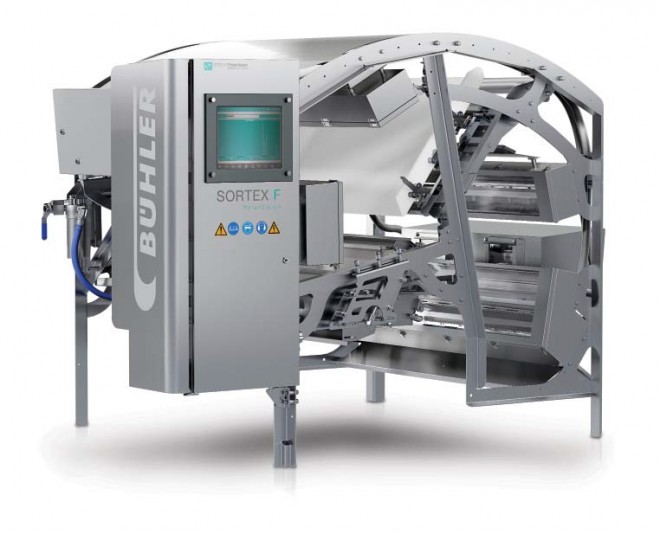

The new SORTEX® F optical sorter for frozen fruits and plant microprocessors promotes clean design boundaries with the most open and accessible frames on the market. Combined with breakthrough technology breakthroughs include SORTEX® PolarVision ™ detection system and new LED-Xenon for unprecedented faults.

and detecting foreign material. SORTEX® F is designed to be placed behind the IQF or in the packaging line to remove rough and delicate color defects,

exotic vegetables and hazardous materials with market leading results.

■ Open frame with sanitary standards

■ Adjustable UHMW-PE chute

■ Open the container

■ Customizable color camera

■ SORTEX® PolarVision ™ detection system

■ PROfileTM technology (shape)

■ LED-Xenon light

■ 17inch touch screen, user interface

■ ProSortXTM operating software

The SORTEX® E1D provides high performance microprocessors that classify experiences in a small footprint. Designed to benefit the larger classifier for smaller processors, while classifying high quality during freezing. SORTEX® E1D can be used as a versatile comparator targeting color defects and direct forms after tunnel-freezing, mass-to-bulk or at the end of the road, using the camera. Advanced Technology. Products that are discolored or distorted, delicate, non-plant material and fiber can also be removed at the same time with accurate precision.

■ Stainless steel frame for easy cleaning

■ UHMW-PE pipe

■ Two-sided detection

■ Customizable color camera

■ InGaAsHD technology is high

■ SORTEX PolarVision ™ detection system

■ PROfileTM technology (shape)

■ 12.1-inch touch screen, user interface

■ ProSortXTM operating software

Expert SORTEX PolarVision ™ detection system combines pioneering technology for unprecedented, market-leading foreign material removal. Creation

PolarCam ™ technology targets the spectral and spatial differentiation between foreign goods and materials while introducing high resolution InGaAsHD

The camera detects foreign material near the invisible infrared spectrum.

Bühler's high-resolution color camera is designed and custom-built to eliminate rough and delicate color from defective fruit and vegetable applications to increase product quality and uniformity. .

Next-generation infrared technology from Bühler now comes with high defi nition with twice the resolution of detecting foreign material to half the size. With twice as many pixels, InGaAsHD detects the smallest pieces of toxic material not visible in the visible spectrum for an extra layer of coverage.

PROfi le ™ technology intelligently detects and almost exclusively touches the subject, allowing for higher capacity than the shape classification. It can also use a combination of many shape parameters to eliminate the trunk and the bottom

or oversized products at the same time.

256 high speed, high efficiency misting machine eliminates defects and 1200 mm

View width ensures high product flow and low productivity losses.

Ejector + technology, Bühler's most powerful, is now available on SORTEX E1D and SORTEX F optical sorting machines to more accurately remove objects such as stone, glass and lump u products.

The latest update on Bühler's proprietary operating software comes with a fresh, modern interface that is clean and intuitive to use. With creativity

FingerTipControl ™ and Bühler are all new ATOM ™ boards for faster processing

and navigate between screens

Bühler's Global Customer Care provides the highest quality local support to ensure that optical classifiers perform at the highest possible performance, providing optimum performance and earning top profits. Best regards. Customer satisfaction is our top priority. This is why we try to provide parts and wear parts within 48 hours, our best to limit your downtime and maximize your profit.

For customers requesting spare parts available on the site, Bühler technicians have created the appropriate accessories' kits for various machines available. The material can also be removed at the same time. exact accuracy.

AeroDry ™ Dryer, Dehydrated Machine, Oven & Roasting Machine.

Custom designed for unique applications.

Typical applications

- Soak fruits like blueberries, blueberries, cherries, raisins

- Apples, apricots, coconuts

Dehydrated vegetables include onions; spices like coriander, parsley and garlic; broccoli; carrot; Chili; mushroom; alfalfa

- French fries and other potato products

Customer Value:

Superior Airflow Conveyor Dryer System

- Unified air velocity and temperature distribution

- Airflow easily reversed

- Uniform heating through symmetrical fan location

Designed for high sanitation

- 100% welded structure, floor and floor

- Finishing the bed, dressing table and heating compartment

Heavy construction

- The heaviest rating framework and floor covering in the industry

Modular construction

- Assembled and tested at the factory

- Ships into large modules for quick installation and commissioning

Option

Advanced control pack

- Many styles of shoes fit the product

- Knock-down construction option allows field assembly with reduced transportation costs

With the AeroDry line, Bühler Aeroglide offers a variety of thermal solutions for vegetable products. Each dryer is custom designed to optimize product quality and improve operational efficiency.

- Single conveyor belt undergoes a variety of vegetable products.

Multi-tier dryers are an ideal solution for dehydrated fruits and vegetables, as well as the transmission lines where product orientation and stacking are important.

- Impingement Presses provide fast and consistent processing for roasted vegetables.

Clean, consistent, efficient. Clean cleaning is simplified with many sanitary features including complete welded surfaces, on-site cleaning systems (CIPs), complete interior access and scrap collection debris. The special airflow system provides uniform air and air, resulting in product quality, color and humidity. Energy saving is an added benefit for Aeroglide's high thermal efficiency and balanced airflow design.

Flexible installation. Aeroglide module construction

The system is designed for easy installation. Each unit was assembled and tested prior to shipment, minimizing field adjustments. Delivery is made of large modules assembled and assembled in advance. This allows installation as fast as possible with reduced field connection points. Construction field construction is also available for projects with limited space.

Food safety. Clean processing and food safety are important concerns for fruit and vegetable processors. Bühler Group is leading the food safety technology and process development. As an active participant in food safety forums and working groups, we are listening closely to major suppliers in the food industry. These partnerships will lead to new initiatives for safe, clean food.

Even today, Bühler's food processing equipment focuses on hygiene. All designs of the dryer have special requirements of the customer for hygiene and sanitation, including:

- Full interior access for inspection, cleaning and maintenance

- Eliminate concrete collection points with concrete slabs, surface slabs, and advanced chaining and transportation options.

- Enhanced insulation and moisture resistance by doors outside the sanitary

- Continuous internal cleaning with on-site cleaning system (CIP)

- Handle wet water more securely with water troughs

- Remove grease and oil from food area with outside conveyor and bearings

Enhanced Performance. Bühler offers AeroPro Advanced Dryer Controls to optimize the performance and efficiency of the drying operation. Modules Controlling the evaporation and humidity of the system ensures that the humidity of the product is controlled close to the specifications, leading to superior product quality and increased productivity. Increased energy efficiency is achieved with Moisture Control and Energy Monitoring. Together, these controls monitor and regulate the operating conditions of heat such as exhaust and power consumption.

Bonus services

- 24 hour support for Aeroglide customers

- Evaluate dryer performance and mechanical check

- Check the product on the spot

- Spare parts, installation and commissioning

Extends to all brands of dryers

- Workshop on drying theory and maintenance

- Testing facilities

Developed and tested in

Raleigh, North Carolina United States