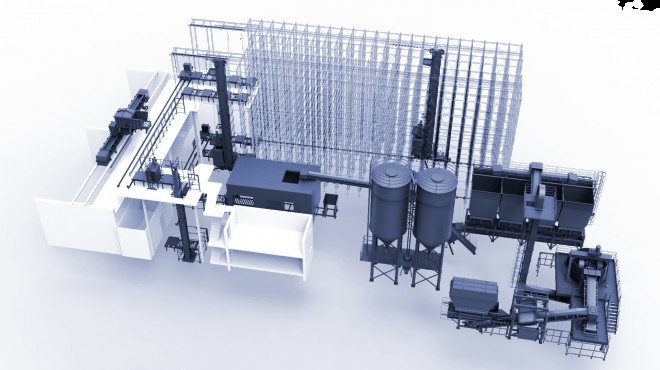

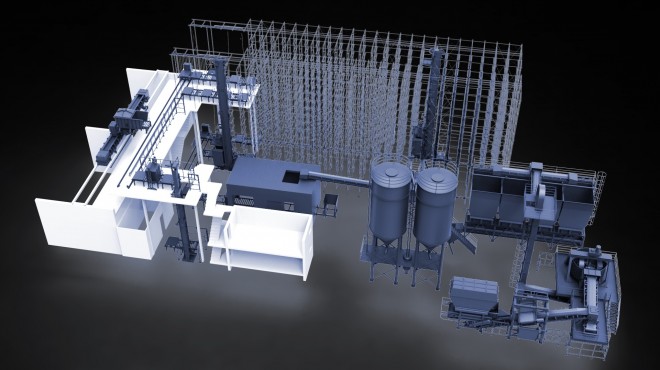

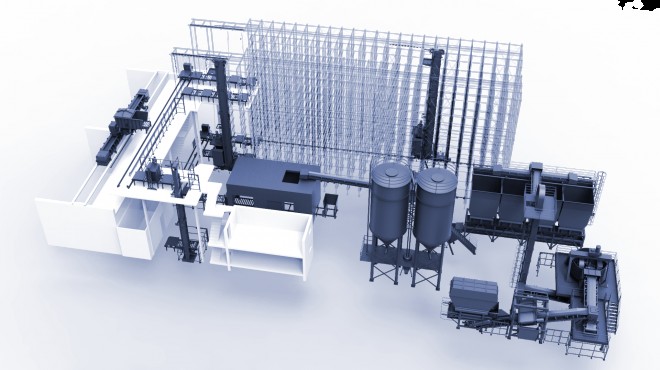

Production plant, unbaked brick - Slovenija

Equipment supply and technology transfer

Pavement pavement factory

More and more concrete products are being produced at manufacturing plants or specialized plants that are being used today, so the choice of products is increasingly diverse and diverse every year. More and more new products are emerging in the market, from different curbs, concrete blocks (bricks), chimney parts, wall tiles, fences and fences to products. Same for construction and landscape planning around the house.

An introduction to the paving of the pavement

More and more concrete products are being manufactured at manufacturing plants or specialized plants that are being used today, so the choice of products is increasingly diverse and diverse every year. More and more new products are emerging in the market, from different curbs, concrete blocks (bricks), chimney parts, wall tiles, fences and fences to products. Same for construction and landscape planning around the house. There are many special blocks. This is probably the most popular concrete product, so their production is undergoing constant change and development, leading to the availability of many types of blocks of various sizes, shapes, colors. and very big end. With these products, it is safe to say that imagination is not limited because of the different paving techniques and combinations that can achieve a completely unique atmosphere around an individual home. or a larger space in the metropolitan area. By using decorative concrete products such as, for example, troughs, fountains and fireplaces, can turn our surroundings into an attractive and aesthetically pleasing habitat.

The rapid development in the production and use of concrete products is certainly possible due to the development of technology for production, as demand for increasingly stringent quality has been established. Only high-quality products can stand out among the diverse range of products. Contemporary production lines for concrete products are automated to a large extent and do not require many employees for their operations. These are mainly operators, managers and supervisors, some regular maintenance workers and cleaners, and some transport workers to provide raw materials and to operate end products. same packing. Very few manual laborers participate in the entire production process, as most activities are controlled by computers. Monitoring systems for some components are designed to eliminate any errors that occur during operation. For example, it is important that the products have the same height, so continuous measurements are made and the system compensates for any possible difference by increasing or decreasing the amount of concrete during impact monitoring. of this change. In this way, the greatest repetition of production is ensured, which is a very important factor. The technological solutions of the production line incorporate the latest innovations in concrete products - from the integrated equipment to the mixing and preparation of concrete to the production in the machine in which a product is shaped. into. In addition, systems for the addition of additives and color pigments are installed, enabling the production of products in a more challenging shape and shape. Contemporary urban architectural designers no longer adapt to the use of asphalt in the last place: instead, they increasingly recommend the use of concrete products. This makes it possible to achieve a more dynamic and colorful final appearance using products made from natural materials. Concrete blocks can be reused if for some reason the digging of the paved surfaces is necessary. A very important environmental effect can be achieved by combining concrete paving elements in cities since the concrete surface is still water permeable, resulting in a reduction in the load of meteorite canals under heavy rainfall. and reduce the likelihood of flooding. Besides,

In briquettes, briquettes are made from waste and raw materials, increasing the efficiency of using raw materials in the manufacture of stone wool and reducing the impact on the environment. The amount of solid waste in stone wool mills is reduced to practically zero with the installation of a bakery unit to recycle waste. Waste from the kilns and grinders is used, along with waste products, cutting edge waste from the production line, plates used from the filter and a small portion of the raw materials used for the cake. , and cement is used as a binder.