SOLUTIONS ARE PERFORMED FOR MANY MORE CUSTOMER VALUES

Manufacture and supply of equipment and technology transfer (Germany).

Production, equipment and technology transfer (Germany).

Minimills are part of our DNA. We pioneered the idea of an integrated plant that included arc furnaces and composite rolling mills - making it a reality. Today, SMS minimills always bring the best results and the shortest break time. You will always get integrated automation solutions that are integrated to increase productivity and reduce manpower. All this ensures you get fast return on investment.

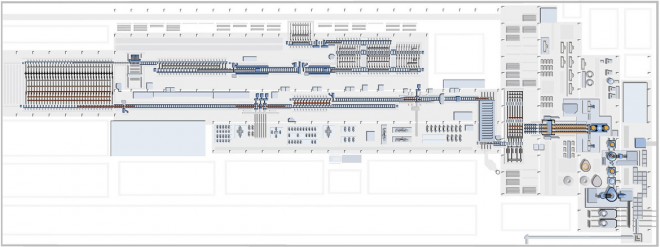

THE CONCEPT

Product range

Always the right choice, from beginning to end

Our molten stores and rolling technology have set the standard for long-term minimill products with capacities ranging from 150,000 to over 2,000,000 tons per year. Here you will find the most complete range of products in the industry - whether it's rollers and rollers, or straighteners and SBQ steel bars, sections, rails, or pipes. Whenever possible, we combine leading-edge technology with top quality from well-known brands, all of which have become part of the SMS group over the years. Included here are ABB, Mannesmann Demag, Schloemann, Siemag, MAN-GHH, Krupp, Möller & Neumann, Sack and many others. All this ensures you have smooth processes and perfect product quality.

MATERIALS

Minimills are always tailor made to the materials that best meet individual needs, be it scrap, DRI, HBI or hot metal.

Scrap / DRI / HBI storage, handling and charging system

Hot metal treatment system and charger

MAKE IT

Integrated process automation and solid mechanical design allows for maximum production with minimal production cost. Modern technologies ensure minimal emissions.

AC & DC Arc Furnaces

Chemical energy technology

Primary scrap system

Heat treatment plant

Material handling system and additional systems

OPTION

The second metallurgical system is designed to achieve the composition and temperature of the fast-fit steel as quickly and efficiently as possible.

Furnace

Vacuums

Oxidized oxygen

Metallurgical heat treatment station

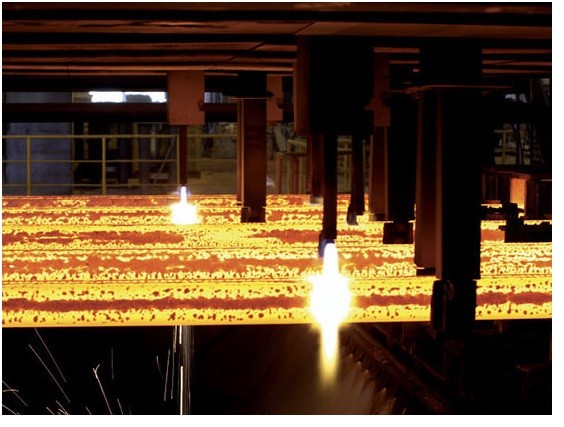

CASTING

Casting machines for processing workpieces, hatches, rings and beam gap from construction steel to quality products for high end applications.

Beam blank casters

Combi casters

Billet casters

REHEATING

The SMS Minimill Group provides the right solution for every steel product. Innovative technologies help manufacturers reduce resource consumption.

Pusher heating

Walk to the fireplace heater

Fireplace heating

Induction heating

ROLLING

The plants are reliable, flexible and most efficient. This ensures the lowest operating costs, strict tolerances and optimum surface conditions.

• Factory Bar

• The factory produces special quality bars

• Rolling mill and rods

• Milling and embossing machines

• Railway Factory

FINISHING

Save time, space and cost: the perfect finishing line prepares all products for storage and shipping.

• Wire

• coil wire

• High-speed distribution system

• Closing

• Heat treatment

• Wet and warm up

PRODUCTS

Minimills manufactures a wide range of steel products. Tailor-Made factory from Minimill SMS team is always the right choice.

Wire and scroll bars

Trader Straight and Bar SBQ Section

Railways and special sections

CMT ® TECHNOLOGY

Direct link between rolling and rolling machines

Our CMT® technology eliminates the need for handling and heating by linking the caster to the factory. An induction heater allows you to perfectly control the starting temperature for rolling mills - according to the speed of the steelwork. Using CMT® technology means that no foundation works in the furnace area and no need to store the workpiece. Environmental aspects of the factory reference Tung Ho demonstrated:

Savings of 72,000 TPY of CO2 emissions (greenhouse effect)

Saving 410 tons of SO2 emissions (acid rain)

Save 225 tons of NOx emissions (acid rain)

DỮ LIỆU QUAN TRỌNG CỦA BỘ LÀM NÓNG SƠ BỘ

- Hệ thống sưởi cảm ứng để sưởi ấm lại và cân bằng trục của

phôi từ CCM đến RM - Phạm vi tốc độ từ 0,07 đến 1 m / s

- Kiểm soát nhiệt độ hoàn hảo kết hợp với tốc độ phôi thép

- Hiệu suất lăn hàng đầu và tính linh hoạt

L

YOUR FEEDBACK FROM CMMM MINIMILLS

Low operating costs (~ -20 $ / t OPEX)

Low manpower requirements

The cost of capital investment is low

Compact design (less construction area, cranes, required soil, etc.)

Low total cost (~ -50 $ / t CAPEX / OPEX)

Reduce emissions

Purchasing and selling local scrap (low cost, less competitive)

REFERENCES

Small stand for key for paragraphs and pictures

Optimal equipment for keys for beams and sections

MORE INFORMATION

Minimill with breakthrough energy efficiency Image

Minimill with breakthrough energy efficiency

MORE INFORMATION

Bar mill is designed with long lasting

Bar mill is designed with long lasting

MORE INFORMATION

SERVICE

SERVICE

https://www.sms-group.com/fileadmin/_processed_/a/f/csm_N-SMS0839-110r_Consulting_Training_5a05279410.jpg

Consulting & Training

Build on experience

However, not just a service partner for your machines and machines, SMS groups are also available for your employees. Moreover, you can participate in the standard and customized training programs designed for you by our SMS TECademy. That assures you to strengthen your capacity as a factory owner.

MORE INFORMATION

EDOC

Document Number: The first step to a smart factory

More information

EMERGENCY - EMERGENCY SERVICES

To easily identify defects and malfunctions and quickly initiate measures to eliminate errors.

More information

CHECKING DEVICES

Regular inspection and maintenance is the basis for effective protection of your equipment.

More information

LONG-TERM MAINTENANCE SERVICES

The SMS team offers you full range of services along the value chain, while you can focus fully on your core competencies.

More information

REFERENCES - SAVE IN ARCELORMITTAL

Establishment of a warehouse for shipment for the purpose of spare parts and wear. Access to the global search network of the SMS Group.