Processing Plant (Milk-Butter-Phomat) - Denmark

Supplying equipment and transferring production technology

For larger integrated projects in the dairy and powdered milk business, SiccaDania provides project management and integration of complete projects in processing equipment. Starting from the raw milk or flour mix, we handle liquid handling, heat treatment and UHT, homogeneity, product concentration, spray drying, powder transport and storage through packaging.

SiccaDania possesses know-how and close cooperation relationships with technology leaders in various unit operations. SiccaDania is free to partner with the best technology companies for personal applications, often not the case with some of the other global equipment providers in our industry.

Complete processing plant

SiccaDania has the capacity required in many technologies associated with the main product distribution program. This is especially true for starch and milk. In close cooperation with professional companies, SiccaDania acts as the main contractor for turnkey projects including wet processing, powder processing, powder packaging and liquid separation.

Effective project management involves core technologies and by selected technology partners establishing SiccaDania as a reputable alternative power plant vendor in the market.

Core solutions and products

SiccaDania offer: SiccaDania designs, engineers, supplies, installs, commission and service the dryer, evaporator and related equipment used in the dairy, starch and food industries. .

Spray dryer

Spray drying is one of the most widely used unit operations in the food and dairy industry. With different sizes to produce a few kilograms or higher pulp volume per hour, SiccaDania offers one, two and three stage dryer designs in combination with wide-body and tower-shaped drying units.

The design of the chambers is closely tied to the requirements of the dryer and powder requirements. Dry spray not only allows the conversion of liquid into powder. This is the most efficient means of achieving exceptional powder properties of particle size, residual moisture, degree of accumulation, high density ... and this does not discriminate the volume. SiccaDania offers the latest design of spray dryer by wide technological know-how in the company in this precision discipline.

Engineers from SiccaDania turnkey projects where spray dryers are available, because the company owns the know-how of upstream and downstream processes, such as pre-processing food (mixing, homogeneous, heat treatment) and agglomeration, cooling, conveying and packaging.

Liquid bed

SiccaDania offers a wide range of liquid bed dryers for different applications. Liquid bed is usually attached to the drying chamber to form a second or third stage during drying. In the process, the powder emitted from the spray dryer can be agglomerated, dried, lecithin and / or cooled in the liquid chamber before packaging.

SiccaDania also offers liquid beds as independent plants.

Zeta dryer

Zeta machines are developed by SiccaDania to provide an optimal drying solution for high viscosity products. Liquids that contain insoluble solids that can be purified by the machine in filter or liquid filtration equipment are usually of consistent consistency that are no longer easily pumped. As it is possible to save on process costs in reducing water as much as possible through mechanical water reduction, the Zeta dryer is an ideal solution for drying products with moisture. The energy cost per kilogram of dry powder produced will fall sharply when compared to spray drying.

The Zeta dryer system consists of a single screw feeder that allows stable drying and easy control. Natural gas, steam or even electricity can be used to heat the process air before going into the drying chamber. The drying chamber has a rotary knife set that decomposes the moisture content of the product in the presence of heated air. The moisture immediately pops up and the dried particles are formed. Particles of air lead to the dewatering system, typically filter bags.

All essential process parameters are controlled via a central control system. Additional features can be added to the system, such as powder cooling, packing-off, different types of air heating etc.

Zeta dryers are widely used to dry proteins, fibers, and chemical products like paste.

Flash dryer

SiccaDania offers a flash dryer system designed for drying starch.

These systems feature the latest sophisticated, energy-efficient design when compared to traditional drying concepts in the market.

SiccaDania has both supply and exhaust fans. This allows the dryer to operate at neutral pressure at the feed input, thus simplifying the product introduction into the dryer.

Evaporator tube

SiccaDania offers a range of evaporators, mainly drop-in-line evaporators. The two main principles of evaporative compressed air used are mechanical compressors (MVR) using large electric fans, and compressed heat (TVR) with steam injection.

The decision to apply the MVR or TVR principle depends on the capacity, the required concentration and the total cost of ownership (TCO). A more economical solution often incorporates the MVR principle to eliminate most of the water phase, and then applies the TVR principle as a complete machine to achieve high concentrations.

SiccaDania supplies evaporation from a pilot scale capacity to about 80 tons per hour of evaporation.

SiccaDania's small-scale spray dryer is designed for the drying of liquid products into powder. Extensive spray drying and small size flake dryers are available in a variety of configurations that allow for greater simplicity of the industrial dryer process.

They are targeted for small-scale production as well as R & D and are widely used by companies and universities around the world. They are available in a standard version and also have a variety of optional modules, thus allowing customization to suit individual requirements. The dryers are manufactured in hygienic designs and include state-of-the-art safety, hygienic and sophisticated PLC-based control systems. All parts exposed to the products are made of stainless steel and all elastomers are foods approved by the GMP standard.

Infant formula

Infant Formula Milk consists of different ingredients, a combination of protein, carbohydrates, vitamins, lipids and minerals. Manufacturers aim to build recipients who have a composition of breast milk, but there are also recipients who meet the typical needs of infants of different ages. Infant milk production usually involves the processing and mixing of flour, liquid processing and heat treatment, evaporation, spray drying and packaging (bags, cans or bags). Installation of infant milk production lines involves a great deal of capacity not only in the field of process equipment but also in the validation and in an integrated approach to project management related to the home. Building contractor. SiccaDania offers complete project management and integration solutions in this field.

Several aspects must be considered when designing a new infant milk production line. When dealing with processing plants for the baby food industry, safety and reliability are the most important focal points of the processing plant supplier.

Usually an infant formula process consists of a number of processing units, depending on the raw product available. Recipes are the knowledge of the manufacturer and "design" but often the ingredients of infant formula are fat, protein and carbohydrates, vitamins and minerals, according to breast milk proportions. There will be differences in recipes based on the age of the child as well as any allergy reservations.

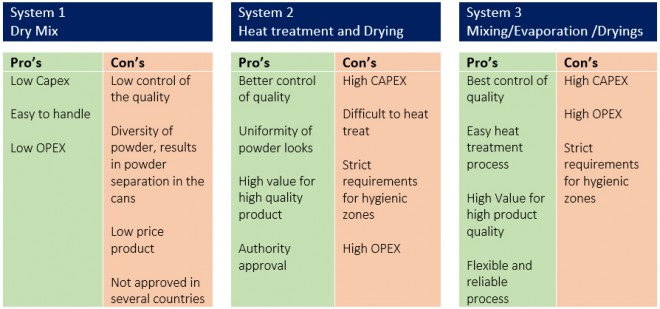

The flour processing line can be designed in three different ways. The design of the manufacturing unit is based on the production process of knowledge and experience.

The diagrams below illustrate three different approaches to producing infant formula powder.

Production of infant milk powder

1. Powdered dry mix only if all the flour is mixed according to the formula of the special formula.

2. Powder is dissolved in water and mixed with a dry substance about 48% before the solution is heat treated and dried.

3. All ingredients are mixed in a solution to about. 32% dry matter before heat treatment and evaporation

Whether choosing a processing line with another chain, must be determined based on the current situation and product. However, below is a series of pro and con for three types of process lines.

What does product quality mean for infant formula powdered milk?

Two aspects of infant formula quality are the focus, one is food safety and the other is nutrition. As a process engineering company, we can help improve both aspects by accurate and careful design of process equipment as well as ensuring perfect production capability. There are also more quality points to consider such as the solubility, flowability and bulk density of the powder that can all be controlled during drying by choosing the correct design for the dryer. as well as setting the drying parameters for the recipes.

Usually this process is divided into wet treatment and dry phase treatment. The reason for doing this is related to the remaining water activity in the product. As long as there is water in the product (liquid phase), the area considered as medium care area, when water is removed from the flour product is now final and will no longer receive any heat treatment. , meaning that this area is now highly carefree, and there is no water in this area. Water creates the possibility of bacterial growth and bacterial growth in infant formula in all cases unacceptable. Another reason to keep the water level low is to extend the life of the powder. Just a few percent moisture in the powder can make a significant difference

How does the manufacturer of the processing equipment help to ensure the quality of infant formula?

Once the overall process has been decided, more details on the design and configuration of infant formula should be made. The design of heat treatment, evaporation and drying will ensure the quality of the final powder. Heat treatment prior to evaporation and / or drying is essential to ensure that microbial growth is controlled during processing and will also improve the life of the product. The evaporation process will be carried out lightly so as not to damage the nutritional value of the product and the drying process will ensure the final quality of the flour such as the solubility and powdered density corresponding to the scoop measures. product.

The overall control and automation system will automatically control the process and at the same time it will be able to secure access to the raw material.

Many other aspects of infant formula powder can be discussed and described, and SiccaDania will be happy to assist our customers with our many years of experience in evaporating and drying applications. . SiccaDania can design and manufacture a processing plant that will provide the freshest infant formula powder that is of the highest quality and safest for babies.