Power Plant, used for gas fuel - Finland

Equipment supply or general contractor EPC - Finland

Gas plant

The Wärtsilä gas-fired power plants use the most economical, natural gas, and clean fossil fuels. This is possible due to the high efficiency of the load and the superior flexibility to start and stop as required.

In addition to efficient and flexible combination, these gas plants also provide low emissions, and can provide large amounts of electricity at a reduced area, making it the optimum solution. It is a priority for sites to minimize environmental impacts. As such, they can be placed near the consumable nodes, optimizing the electrical system.

Wärtsilä gas power plants can run on natural gas, LPG and other biogas

Benefit

Plant power efficiency is up to 50% in simple cycle and 54% in combined cycle mode. Only 5 bars require operating pressure, meaning no compressed air is required at the plant. Automated fuel technology ensures very low emissions, in line with most regulations, including IFC (World Bank Group). By adding an SCR (selective catalystic reduction) unit, even the most stringent standards around the world can be met.

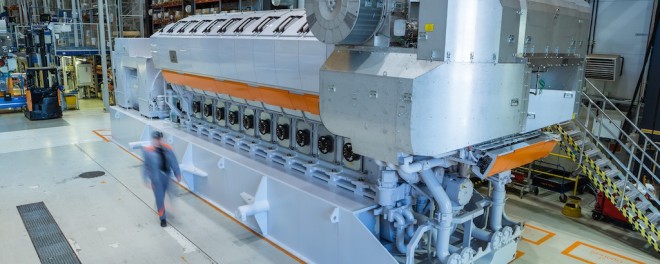

WÄRTSILÄ 31SG

WÄRTSILÄ 31SG NEW STANDARD FOR A NEW STANDARD FOR EFFICIENCY, FLEXIBILITY IN OPERATION AND RELIABILITY AND POSSIBILITY OF SERVICE

Generating set type: 20V31SG

50 Hz 60 Hz

11783 kW 11391 kW

Wärtsilä 31SG here to provide a step change!

The Wärtsilä 31SG engine sets a new standard in the production of gas engines. Technological advances in efficiency and O & M will reduce overall lifecycle costs for power plants based on Wärtsilä 31SG.

WEBINAR RECORDING

Sharpen the edges of the value - Wärtsilä 31SG

Efficiency is an important factor in modern electricity generation. We want to improve the performance of our customers. By bringing the Wärtsilä 31SG on the market, we allow our customers to make a leap in efficiency and reduce overall lifecycle costs.

What the new Wärtsilä 31SG offers

Wide range of loads

• Two-stage boosting speed

• Gas, oil and dual fuel modes

• Hydraulic valve structure

• The next motor control system

• Improved output

• Improved efficiency

• Reducing emissions

• Higher availability

• Longer components life

• Lower overall life cycle costs

• Low load operation for rotary reserve

• Fast start, loading and unloading for dynamic markets

- 2 minutes for full download from standby

• Higher energy density throughput

The most efficient internal combustion engine

• Fuel injection controls Digitally

• Fully adjustable semi hydraulic valve actuation (VIC / VEC)

- Variable input valve time

- Variable valve timing

• Two-stage boosting system

• New generation UNIC motor control system

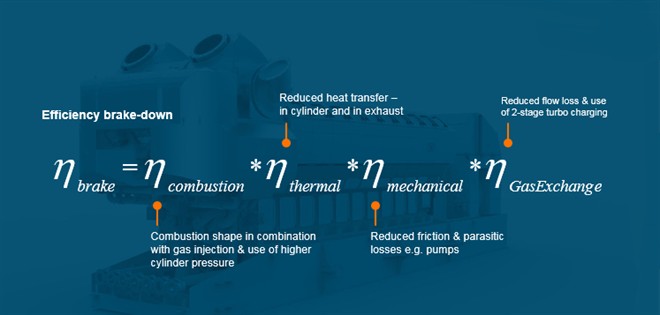

All areas related to efficiency have been improved on the Wärtsilä 31SG allowing for effective change steps.

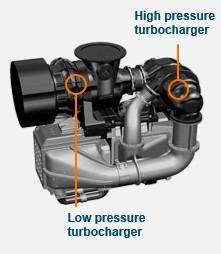

Booster system

The two-phase turbine allows high efficiency throughout the load

• Improved resilience using the concept of cartridge to remove compressors and turbines

The two-stage turbocharger allows for increased performance and operational flexibility

Wärtsilä's R & D team has worked hard for many years to develop this advanced tool. The core of the design is based on Wärtsilä's long-standing and strong market knowledge and understanding of customer needs. row. Quality has been the basis of the R & D process from the very first steps.

Wärtsilä 31SG, the most efficient 4-stroke engine in the world

In the price sensitive field of power generation, efficiency and flexibility are the hottest items. Wärtsilä's latest engine marks a change in both, bringing the top economic efficiency to over 50%. The secret to its success is a new design, perfect from the start, making it hard enough to withstand the mechanical load associated with two-stage turbocharging.

Internal combustion engines have been through a lot since they appeared nearly 200 years ago. It is fascinating to think that, despite all the progress made over decades of blurring and refining, this 18th century concept continues to be the basis for today's electricity generation. And consensus is that there are still many ways to improve design simply to be made and tested.

In this way of thinking, six years ago, Wärtsilä's engineers set up something quite rare among the major engine manufacturers. Instead of improving the current design, they start from a completely empty table to develop a new engine family that can be significantly more efficient than anything that has ever happened before.

Output: Wärtsilä 31, available in diesel, dual fuel and pure variants. The last one is the spark-ignited Wärtsilä 31SG, a 20-cylinder version with a capacity of 12 MW. When the first Wärtsilä 20V31SG was released from the production line this year, it became the world's simplest combustion engine.

The specific characteristics of the Wärtsilä 31SG are the ability to achieve efficiencies exceeding 50% - a milestone in the industry. For comparison, simple gas turbines typically produce about 40% efficiency. Wärtsilä's existing generators have far exceeded the mark, but the new engine extended the distance further, demonstrating significant savings potential for power producers as well as lower emissions. .

Effective under pressure

Designing a completely new bottom-up engine gives Wärtsilä engineers the unique opportunity to test all of the different factors that contribute to improving engine performance, step-by-step improvement to achieve profitability. maximum benefit. The combustion quality, engine parameters, temperature and flow loss prevention, and internal friction are among the issues to be explored and addressed adequately.

However, the most important step in the Wärtsilä 31SG is the engine structure clearly designed to use a two-stage turbocharger. While the dramatic increase in performance associated with the two-stage boost is well known - the industry has tested it for some time - no current engine can take advantage of it. They simply can not stand up to the load and the stress is the result of the step change in the shot pressure. To overcome this, the engineers gave the engine structure of the Wärtsilä 31SG a very powerful design with moderate effective breaking noise (BMEP) of 30 bars.

Of course, having a design that combines the concepts of effective driving is one of the things while bringing a new engine to life. Development of the Wärtsilä 31SG is a long and complex process involving extensive computer simulations, testing on a single test engine and then testing on a number of multi-cylinder engines. All this is done to ensure that the effective benefits are realized and that the final product will meet the highest standards of reliability.

Flexibility for today's electricity needs

A fundamental advantage of the Wärtsilä 31SG is its versatility - its rapid startup and high efficiency throughout the load.

This is extremely important in the context of today's power generation, where robust growth of renewable resources has caused disruptive change. Often the facility is disappearing as generators assume a new role in continually backing up the grid as production from renewable sources decreases. This change represents a major challenge for plant owners. Mixed cycle power plants can not cope with daily operations, stoppages, and constantly changing load models are becoming a new benchmark.

On the other hand, the internal combustion engine is just the right tool for the job thanks to its flexible operation. Needless to say, engineers want to push the versatility of Wärtsilä 31SG to the cutting edge.

A major contribution to the increased dynamics of the engine is the completely redesigned valve method. The new design replaced the mechanical valve mechanism of the previous models with a hydraulic system, similar to those used in the automotive industry. This feature allows very precise and smooth valve timing to ensure that the fuel and air ratio in the cylinder is always optimized. In this way, the engine can utilize the maximum power of the two-stage turbocharger, namely the part load.

Optimized engine parameters and timing of intake valves combined with electronic ignition time lead to less flammable hydrocarbons and thus improve efficiency and lower emissions regardless of load . An additional bonus of the hydraulic valve start concept is that there is no need to adjust the valve discharge.

The versatility of the Wärtsilä 31SG can be overstated. The engine can be operated continuously at a load of 10% and can reach full load within just two minutes of starting command.

Control all

Automation is an important element of any modern gas engine, as a basis for efficiency, safety and flexibility, but there are special requirements for advanced and complex machinery. Wärtsilä 31SG. With 20 cylinders each shot six times per second and a lot of variables into play, the ability to easily harmonize and control every aspect of the operation is absolutely important. Exactly, cylinder-specific control algorithms are essential for a gas engine to operate with this high pressure.

For this reason, as part of the development of this engine, Wärtsilä has come a long way to creating a new generation automation system that is integrated into the engine. The engine automation system is built entirely in-house based on new hardware and software.

The auto-engine system is specifically for the widespread implementation of digital controls, valve timing, air intake, ignition, temperature cooling and various aspects of turbocharging. This high degree of automation allows the Wärtsilä 31SG to take into account fuel differences as well as operate on different loads without compromising efficiency.

New, modular and integrated automation hardware. All sensors are directly connected to the control ports, not through the connectors or junction boxes - a change that reduces the probability of error. The device also undergoes rigorous vibration and temperature testing to ensure that it will withstand the tough environment of the engine room, enhancing reliability.

Long look

The advantage of a more efficient engine such as the Wärtsilä 31SG is evident at times when fuel prices are relatively high. However, interest in the engine has been strong in all of our markets, although gas prices in certain areas are quite favorable at this time. Today's investors find that one of these types of engines is long-term investment and fuel prices can fluctuate year by year, from one decade to another. These investors have a holistic approach, seeking both lower life-cycle costs related to maintenance intervals, and a buffer against potential changes in the fuel market.

On a global scale, the world could significantly reduce emissions of fossil fuels in the coming decades. This change will occur not only from higher fuel prices, but also from political pressure leading to emission limits. Solutions that exist during the test will be the most flexible and effective solution. In both categories, Wärtsilä 31SG has a clear advantage. This is an engine built for the future.