Masa – Nhà cung cấp TB máy gạch bê tông – Germany.

Cung cấp thiết bị và chuyển gao công nghệ sản xuất

Masa - Supplier of concrete brick machines - Germany.

Masa is a leading supplier and manufacturer of plant, machinery and parts for the building materials industry. Our clients are companies on all continents specializing in the manufacture of building materials. Our name is synonymous with innovative and powerful design concepts, advanced technology and maximum safety. These principles are fundamental to "Design in Germany".

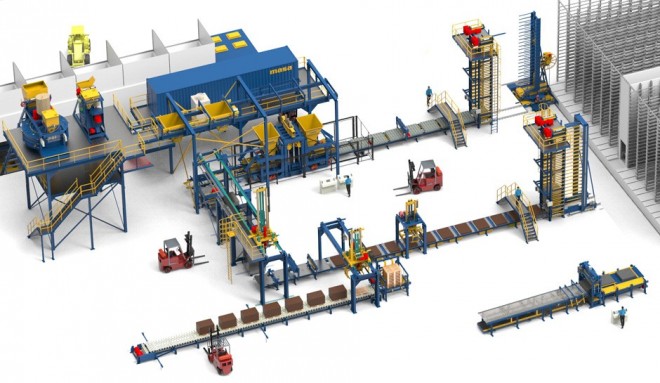

Production of concrete blocks

It's a long way from material through the mix to finishing stones. Find out about our concrete block making machines.

It is a long way from material through the mixture to finish the stone. Many plant components are involved in this process. Only when the system components are combined can one be assured of a smooth process and economic operation of the block plant.

Concrete Concrete Production

Powerful and intelligent factory concept from a single source.

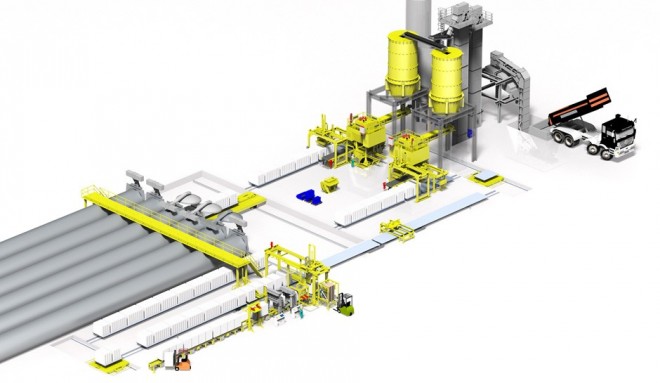

Learn about our AAC manufacturing facilities.

The production of automated aerated concrete products requires a high standard for the mixing and quantification of aggregates, fermentation control and step-by-step production control. Masa's aerated concrete equipment is proven to be state-of-the-art process technology designed to meet the needs of our customers. This approach allows for complete solutions to ensure high efficiency, optimizing processes leading to consistent product quality.

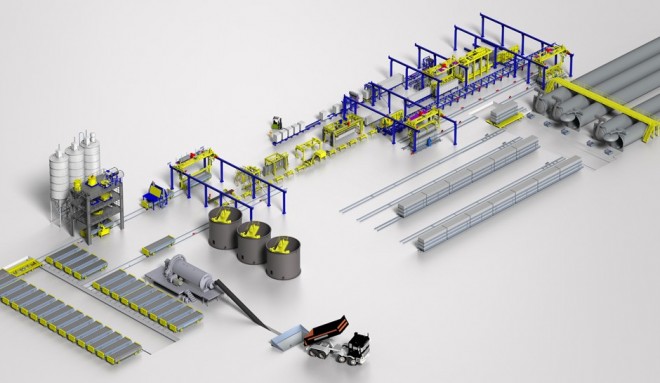

Production of sand tile

It is a long way from material through the mixture to complete sand lime sand. A lot of ...

Learn about our sand lime production.

It is a long way from material through the mixture to complete sand lime sand. Many plant components are involved in this process. Only when the components of the system are paired can one be assured of the operational and economic operation of the lime brick factory.

Learn more about Masa-LithoPore®

Masa LithoPore® is a mineral construction material that is processed into a heat-absorbing ...

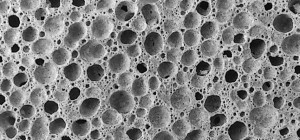

1. What is Masa-LithoPore®?

Masa-LithoPore® is a mineral construction material that is processed into volatile insulation.

Masa GmbH has signed a cooperation agreement to develop and produce Masa-LithoPore® with Luca Industries International GmbH, one of the leading companies in the field of bio-chemical and chemical product development and production.

As of 14 January 2015, the development stage can be completed with the general technical approval of the DIBt (Deutsches Institut für Bautechnik, Institute for Structural Engineering of Germany).

Under the Masa-LithoPore® brand, both partners work together to provide a complete system for the production of insulating panels.

2. Advantages

Masa-LithoPore® products can replace conventional insulation materials, such as expanded polystyrene (EPS) or mineral wool.

The insulation values obtained can also be compared to other insulating panels.

The main advantages are:

Non-combustible mineral material (construction grade A1)

operated by capillary and vapor, thus suitable for interior insulation (without the use of a vapor barrier) environmentally friendly and easily recyclable easily handled on the construction site DIBt has been approved

3. Specifications sheet of the product

Prefabricated panels using Masa-LithoPore® technology have the following technical and physical characteristics: Standard products:

Masa-LithoPore® 75 Masa-Litho-Pore® 150

Dry density DIN EN 1602 [2] ρ105 ° C 5 - 85 kg / m3 140 - 155 kg / m3

Thermal conductivity DIN EN 12667 [13] λ10, tr ≤ 0.0398 W / m * K ≤ 0.0518 W / m * K

Compressive strength DIN EN 826 [4] σ 10% ≥ 40 kPa ≥ 220 kPa

Tensile strength DIN EN 1607 [5] σmt ≥ 10 kPa ≥ 20 kPa

Bending strength DIN EN 12089 Methode B [6] σb ≥ 10 kPa ≥ 60 kPa

Water absorption DIN EN 1609 [9] Wp, 24h ≤ 3.5 kg / m2 ≤ 4.5 kg / m2

Fire behavior DIN EN 13501 A1 class A1

Vapor permeability DIN EN ISO 12572 [10] μ ≤ 3.0 ≤ 4.0

Masa-LithoPore® includes water and additives. In addition, water is needed for the production process. In a two-stage process, the basic materials are mixed and molded. The filled molds are then transported to the area prior to hardening. Once the cake has reached the blue (cut), the mold will be removed and the blocks cut to the size of the insulating plate in the cut.

The gear wheels are placed on hard cars and transported to the area after curing. Before they are packaged, the surface of the individual insulation panels can be hydrophobized.

A high quality insulation board requires smooth handling. Therefore, the finished product must be packaged in such a way that it is protected from dirt and moisture before it is removed from the factory. Depending on the plant concept, this packaging process can be done automatically or semi-automatically.

Many components of the plant are required to produce insulating panels similar to the Masa machines used for the manufacture of aerated concrete.

Khả năng của nhà máy:

| Thao tác Shift | | |

|---|

| Hoạt động một ca (8 giờ) | 150 m³ | tương đương 1500 m² với độ dày 100mm |

| Hoạt động hai ca (16 giờ) | 300 m³ | bằng 3000 m² với độ dày 100mm |

| Hoạt động ba ca (24 giờ) | 450 m³ | bằng 4500 m² với độ dày 100mm |