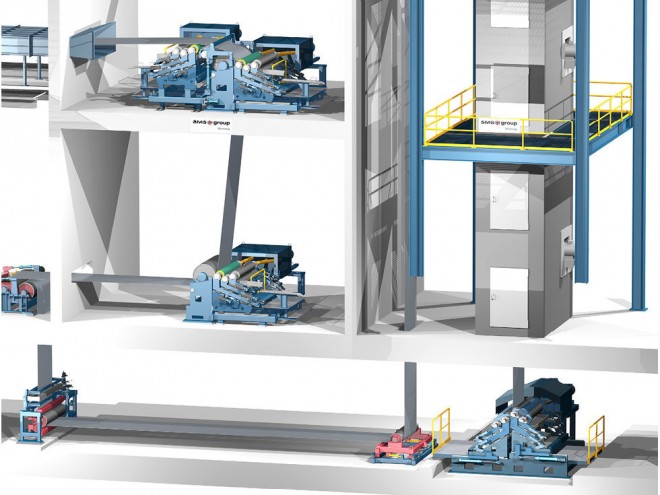

Line of paint equipment for aluminum (Germany)

Line of paint equipment for aluminum (Germany)

Line of paint equipment for aluminum (Germany)

PAINT

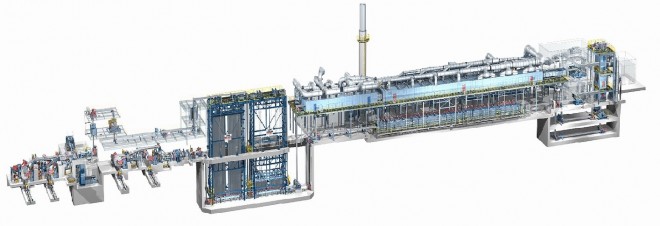

What makes color coatings such an attractive proposition is that they apply a high quality coating to the strip so that it can go directly to the final product processing. This eliminates too expensive phases. Ready for you from the SMS group are the paint layers for different aluminum applications. These lines differ depending on the final use of the material. However, you get the complete line from a single source, all designed to perform some excellent process. Of course, the highlight is always the compact coating process. We guarantee the processing of chemical precursors, paint next, and oven completely synchronized. That way, you will achieve excellent quality with low power and energy consumption.

Line paint color

This is how the process works

First, the surface must be prepared to cover the color. This means cleaning it, then treating it with a passive chemical. Next, the two finishes with highly efficient control systems apply uniform and precise coatings in layer thicknesses. Regardless of the thickness, our line guarantees low media consumption. Here is the kiln, where the solvents are decomposed in a non-contact process. That hardens the color layer on the strip. In order to protect the finished surface and improve the properties of the deep drawing, a wax layer can be applied. This is done in a roll of vertical cuater using hot rollers

TECHNOLOGY

Floating boiler

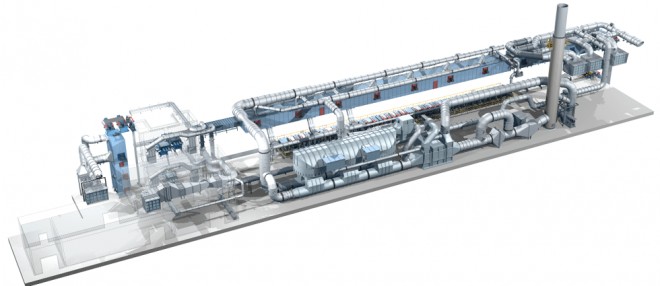

Non-contact and effective drying

Our high performance heat exchanger to desiccate even heated solvents, cooling performance, and particularly high efficiency. It also comes with the top green certificates. To ensure a perfect finish, the strip will not contact the entire furnace.

EXCHANGE BOARD

Non-contact and effective drying

Modular and compact design, high performance convection ovens are prominent for heating and cooling, especially high efficiency and eco-friendly. All this requires setting the ideal control and process parameters. We apply a mathematical model to get this right each time.

Nozzles in the blast furnace make it possible for the non-contact strip to pass through the furnace and the air-cooled sinus-shaped air cooler. This can happen because, throughout the furnace length, the hot air nozzle heats the strips evenly and keeps it floating on the air cushion. Removal of mechanical contact in the furnace transforms into a non-error strip surface. Modular furnaces have several heating zones that use turbines to create an air channel that includes both upper and lower airflow. That makes them easy to control. The air is heated by the furnace working with reheated air, but requires very low input energy.

Oxy

Oxy renewable heat

Technology is designed according to your requirements

Our renewable system (RTO) burns furnace gas in the furnace with a thermal efficiency of 98%. Depending on the amount of solvent in the exhaust air, the afterburner and even the kiln can operate without additional power (self-healing).

OXYGEN TEMPERATURE REFRIGERATION

Coating technology is designed according to your requirements

There is a common principle behind paint coatings: solvents are evaporated to cross-link the varnish molecules and repair varnishes. It is important that three factors determine the choice of heating types for the oven: product portfolio, energy consumption and cost. That explains why automatic ovens are popular for a wide range. Here a renewable oxidation system (RTO) with high thermal efficiency extraction and combustion gases. Depending on the amount of solvent in the exhaust air, you can operate the system after burning without providing additional energy. In addition, if you use an energy recovery system, the same applies to the oven.

Coating Technology

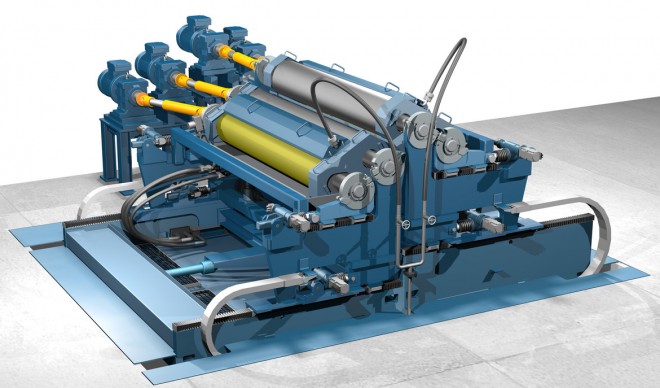

Accurate and reliable

Here, we offer you a wide range of coating systems for colored coatings. Whichever type you choose, you will benefit from top reliability and reliability. Just as reliable as our closed-loop adjustment system is because it ensures the thickness of the coating is correct every time.

COOLING

Before painting, paint should be applied over the surface of the tape. This happens in a vertical roll. Our effective control system ensures a uniform coating at the required thickness at low media consumption. Also featured in our coaters are some circulation systems to quickly change the media. You almost never have to wait because the rollers, pans and vehicle systems are automatically cleaned in less than two minutes.