Sản xuất giấy Kraft , thiết bị ,công nghệ-Autria

Kraft paper production, equipment, technology-Autria

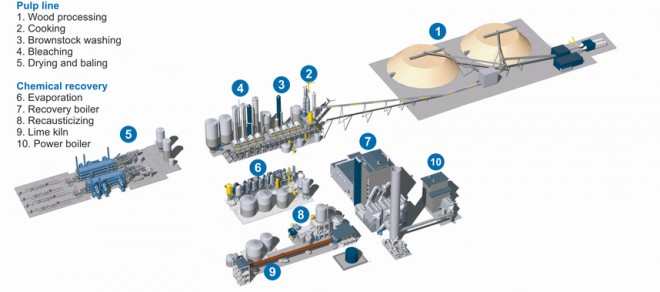

PULP & GIẢI PHÁP GIẢI PHÁP cho ngành bột giấy kraft

Các giải pháp hiện đại cho các ứng dụng giấy lót và giấy bao tải

Andritz's pulp production capabilities

ANDRITZ PULP & PAPER offers one of the world's best technologies and services for the production of pulp - chemical, mechanical or recycled pulp. We provide complete production lines or individual components for your pulp mill.

The primary objective of pulp producers is to achieve a consistent, economical and stable pulp yield with uniform quality. High productivity with low operating costs is as important as saving and saving for people and the environment.

ANDRITZ is one of the leading technology suppliers to provide a complete chemical pulp mill made with the excellence of world renowned environment. Our technology for producing pulp and recycled fiber processing is one of the best available.

ANDRITZ's experienced project teams support you in the design, planning, erection and start-up of your plant. Technical support and service available throughout the life of the device.

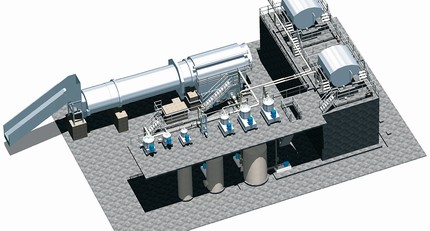

ANDRITZ technology and solutions for woodworking

For all climates, wood and industry

ANDRITZ provides proven and proven solutions for wood processing - in all climates, for all species, and for many forest industries.

ANDRITZ is a leading provider of proven wood processing solutions for the pulp, panelboard and renewable energy sectors. All types of wood species can be handled in ANDRITZ wood, chips, and biofuel plants: from the appearance of logs to their next preparation into the wood chip using the master Essential in kraft and mechanical pulp production line. In addition, this technology is used to process biomass used in energy production.

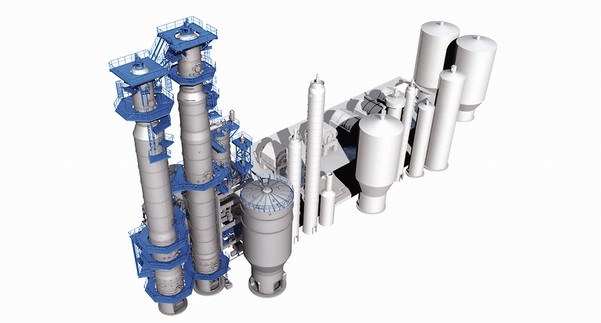

Kraft pulp

Technology for each grinding process, recovery and processing of energy

The main challenges faced by pulp producers are achieving consistent pulp yields with the lowest levels of chemical and water consumption that are most effective. And to do this in strict environmental regulations.

ANDRITZ is one of the few technology suppliers that provides complete pulp mills and performs it with the excellence of the world renowned environment.

ANDRITZ technology to dissolve pulp production

Demand for environmentally friendly yarn sources has increased considerably in the use of soluble pulp, especially in textile processes. ANDRITZ has a cost-effective approach to producing soluble pulp, including continuous automatic hydrolysis with efficient washing machines and other pulp processing equipment.

The main challenges are maintaining high yields and productivity while ensuring consistent pulp quality. ANDRITZ technology for the production of soluble powders is based on years of experience with specialized fiber yarns and R & D specialized in high-molecular-weight alpha-cellulose pulp. Our experience with biofuels continues to lead us to design systems with special features that take into account optimal methods for product recovery and reuse.

Today, ANDRITZ is the only technology supplier to dissolve pulp production with solid references and experience.

ANDRITZ has the experience of integrating all existing process areas with this new technology specifically to solve pulp production problems. The ANDRITZ project team has the experience of assisting you in the engineering, planning, erection and start-up of the pulp production line. Global and local technical and service support is available throughout the life of the device.

ANDRITZ before continuous hydrolysis

The most advanced way to produce instant powder

The key to the successful production of soluble pulp is the effective removal of hemicellulose in the fiber source without damaging cellulose. The pre-hydraulic (PHV) pre-engineered by ANDRITZ is a state-of-the-art technology for producing high quality soluble pulp and other low-cost by-products.

Older methods of pre-hydrolysis of kraft pulp are less than ideal

There are significant challenges in eliminating plasma wastes when producing instant powders with a continuous cooking system. Achieving steady output and avoiding the precipitation of the byproducts from cooking reactions are common problems in older systems that lead to problems of operation and quality.

PHV: Advanced and effective cooking to dissolve pulp

ANDRITZ looked back on the process and redesigned his cooking system to make the removal of hemicellulose much more effective. The foundation for process modification and the manufacture of new equipment parts based on years of experience in the manufacture of pulp for paper. ANDRITZ's previous hydraulic vessel (PHV) gained rapid acceptance and was delivered to some Asian plants where viscose fiber growth was the highest.

PHV uses hydrohydrolysis to remove hemicellulose effectively. This allows recovery of hydrolysates, which contain hemicellulose soluble in aqueous solution. This process is simplified and the cost is reduced because natural hydroxylis does not require additional chemicals to initiate the hydrolysis reaction.

ANDRITZ (PHV) pre-glass hydraulic vessels can be equipped with existing continuous cooking facilities. Installation and commissioning costs may be much lower than traditional cooking systems to dissolve pulp. Yarn yields are several percentage points higher than batches due to the excellent choice of principle reactions and sustained recovery of by-products.

The current practice for treating hydrolysates is to neutralize it and burn it with large quantities of black liquor. However, in the future, this product line can be processed for energy production or as a building block in other value added products, further improving the economics of the process. overall.

ANDRITZ the ability to produce mechanical pulp

While mechanical pulp has many benefits (productivity and optical quality are at the top), as energy costs increase, the competitiveness of muscle fibers decreases. You can benefit from the new ANDRITZ PULP & PAPER technologies that produce high quality mechanical pulp with significant energy savings.

Challenges

The amount of electrical power that can be stored in TMP plants around the world using modern techniques is enormous. Conservative estimates are 70-75% of plants still using traditional technology. A 15% reduction in power consumption will save approximately 750 MW per year. To be effective, energy reduction must be made for both softwood and hardwood.

Solution

ANDRITZ has made great strides in reducing the energy requirements of mechanical processing and improving energy recovery efficiency. The development of chemical treatment methods and leakage equipment has greatly improved the energy / quality ratio. ANDRITZ has developed processes and technologies suitable for hardwood and hardwood processing, as well as for annual grinding.

ANDRITZ technology portfolio for mechanical pulp manufacturers includes high quality equipment for key processes, whether fiber is hardwood, softwood, or even annual plants: woodworking, milling, screening, screening, heat recovery, bleaching,, including automation.

Each component is designed to operate independently in a rebuilt or modernized application, or seamlessly integrates with ANDRITZ's other machinery in a complete installation path.

ANDRITZ's experienced project teams support you in the design, planning, erection and start-up of your plant. Technical support and services are available throughout the life of the device

Processes and technologies are available from ANDRITZ

Process the wood

ATMP

P-RC APMP

Wash

Screening

Bleaching

Recycle / dry pulp

Heat recovery

Pump

Garments are designed

Automation

ANDRITZ deinking system

ANDRITZ Grape Solutions is one of the leading suppliers of complete systems for defecated pulp - from casting to preservation, including sludge treatment and testing. The extensive system knowledge, long experience in building all kinds of wash plants and a variety of equipment is the basis for our leading position.

The benefits of ANDRITZ deinking system

Minimal operating costs through equipment and components are very effective

Low energy consumption

Innovative design for highest efficiency, reliability and quality

Sound environmentally friendly processes and equipment (eg, high unevenness, eliminating the burden and cost savings)

High uptime and availability: Short-term requirements for maintenance, long-term maintenance interviews and minimum downtime.

ANDRITZ deinking system is based on experience and innovation

Global experience from multiple settings allows ANDRITZ to designate and build the right system for your deinking application. From screening, cleaning, flotation, thickening / dewatering, scattering and bleaching, as well as sludge and denitrification - each step is carried out by highly efficient equipment. The entire process chain is designed to improve the quality of pulp and paper - increasing your profitability and reducing your production costs.

ANDRITZ has the right technology and experience to help you handle furniture like OCC, AOCC, liquid packaging, waste mix, etc.

Industrial grade often have more pollutants to be eliminated early in the process before they have the opportunity to decompose into stocks. ANDRITZ offers a wide range of processes and equipment suitable for application to recycle industrial levels.

Prior to developing the device for every step of the process, we had a deep understanding of how individual devices must perform throughout the system. In some cases, this knowledge has helped us combine two steps in one unit - simplifying the arrangement and significantly reducing costs. Hundreds of installations give us the platform to suggest improvements and modifications to each new application.

Key equipment based on experience with all types of furniture

In addition to the traditional industrial processing systems, ANDRITZ recommends FibreFlow pulverizers to ensure high quality pulp. FibreFlow removes contaminants in the early stages of the process. In this way, the purity of the pulp is maximized and less equipment is needed to clean the pulp.

Fiber FibreFlow itself does not produce fine particles or damage fibers. Best quality yarns are maintained. After the drum, ANDRITZ's ModulScreen system can be used to maximize the cleanliness of the pulp. ANDRITZ installation works successfully without detergent and dispersant for some materials and final pulp properties.

This leads to savings in investment, maintenance and energy costs. The ANDRITZ CompaDis disperger, with its innovative technology, is the right choice for dispersion. The heating of the dough is made easily and economically with our thickener. We provide excellent solutions for waste and sludge disposal, as well as water treatment.