HEALTH TECHNOLOGY

PUSHER HEAT PUMP

Heater and efficient embryo processing

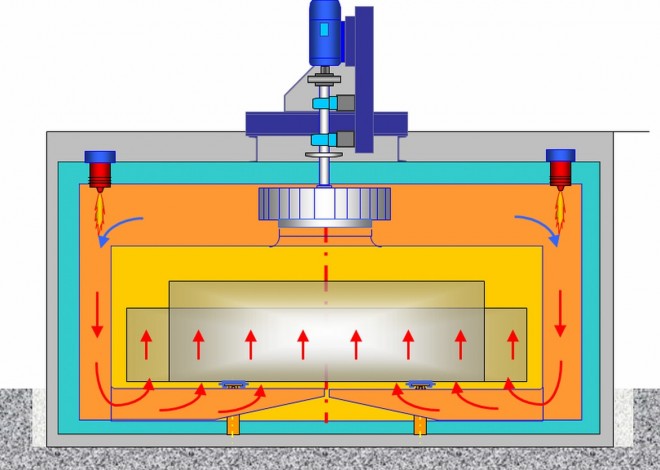

Our aluminum heaters are available in either gas or electric direct-injection versions. Whichever design you choose, your furnace will heat the continuous or semi-continuous rolls efficiently before rolling over. You can also use it to homogenize the bars at higher temperatures. Then, after homogeneous completion, the embryos are cooled down to the rolling temperature. The installation here is a special air guide system to achieve a uniform temperature distribution throughout the heating and cooling process.

SMS TYPE FORM

Heater and efficient embryo processing

Our aluminum heaters are available in either gas or electric direct-injection versions. Whichever design you choose, your furnace will heat the continuous or semi-continuous rolls efficiently before rolling over. You can also use it to homogenize the bars at higher temperatures. Then, after homogeneous completion, the embryos are cooled down to the rolling temperature. The installation here is a special air guide system to achieve a uniform temperature distribution throughout the heating and cooling process.

To create a smooth transition, the furnace is perfectly suited to hot roller roller tables. You also benefit from complete automation - starting with crane embossing to center and weight on the entry board, as well as transportation to the hot plate. In addition there are many heating areas in the furnace, which are heated directly by electrically operated registers or furnaces (recuperative) to temperatures up to 680 degrees Celsius. Burners or registers on the ceiling on either side - with a central fan designed for heat distribution. There is also a special, high-speed air guide system located in between and under the ingots. This ensures perfect heat transfer to the workpieces and uniformly distributes the temperature inside the furnace.

Main features:

Stations for filling workpieces with central equipment, measuring and weighing

To push

Furnace

Air cooler (optional)

Extractor

Downgrade

Hydraulic power supply for each furnace at the entrance and exit

Conveyor back slide

Electric control equipment

HUMAN RESOURCES

HIGH PERFORMANCE, FLEXIBLE DESIGN

Want to increase yield by reducing trimming losses? Our booth is perfect for this job.

COOLING INCREASES

The beauty of conveyor cooling is that it increases output.

Hot-rolled production lines for sale, Aluminum Ma'aden, Saudi Arabia

Continuous Hot Selling Line, Tianjin Zhongwang, China

This hot rolling mill is a continuous 1 + 4 machine with capacity of 650,000 tons per year. It consists of a four-turn roller support with a maximum rolling force of 40 MN and rolling embryos of up to 635 mm thickness. The rolls in the vibrating gears are controlled by a dual drive with a rated power of 2 x 4.500 kW. Downstream, the complete plant consists of four four-storey buildings. They roll the transfer bars 30 mm thick in one down to the final thickness between 7.0 and 2.0 mm. Rolling mills have a maximum rolling speed of 600 m / min and a rolling force of over 40 MN. Fully integrated here is our high-tech actuator to ensure the latest thickness, optimal contour and perfect band surface. We equip the complete rolling mill with our X-Pneumatic ® system and automation system. Another highlight is AluControl®. It provides precise control based on detailed process sequence data plus general information on products for hot and cold rolled aluminum.

Main technical data

Material AA5xxx; AA3xxx

Width range 1,050 - 2,100 mm

Strip thickness 2.0 - 7.0 mm

Coil weight 32 t

Capacity 650,000 tons

PRODUCTS AND SOLUTIONS (GENERAL)

X-PACT ® Progressive Toner

Highest quality even during acceleration and deceleration

More information

X-PACT ® COILER CONTROL

Control system to ensure product quality and stability during the coil

More information

X-PACT ® MILL STAND CONTROL (TCS)

Technical Control System to ensure the highest product quality (HGC, WRB, IRB, CVC ®)

More information

X-SCHEDULED SYSTEM (PSC ®)

Score system set for each pass according to the parameters and limitations of the current process

More information

X-TILE® CONTROL AND ROOM CONTROL (PFC)

Highest product quality in striped geometry

More information

X-TEMPERATURE® TEMPERATURE CONTROL

More information