MANUFACTURE OF SHEETS AND FLEXIBLE OPTICS AND SAVINGS

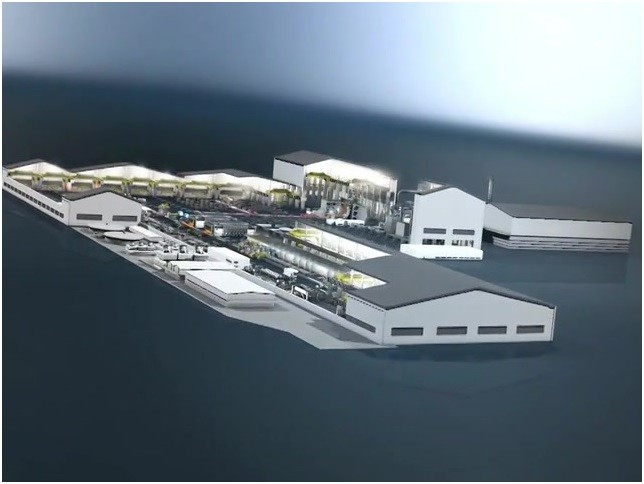

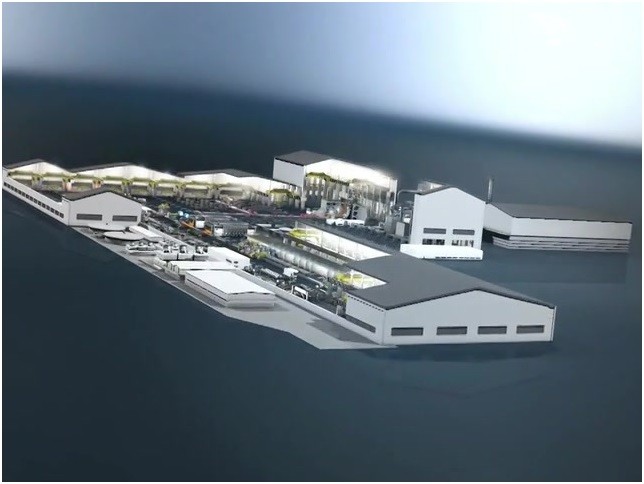

Stainless steel sheet and plate production plant - Equipment, technology Germany

Factory, stainless steel sheet and alloy - Equipment, technology Germany

Our Steckel factory is characterized by their excellent flexibility and low conversion cost. This is a cost-effective solution when rolling stainless steel, special alloys as well as carbon with a capacity of up to 1.8 million tons per year. Our Steckel / Plate mills incorporate Steckel technology and roll plates that allow the production of hot sheets and strips on a single line.

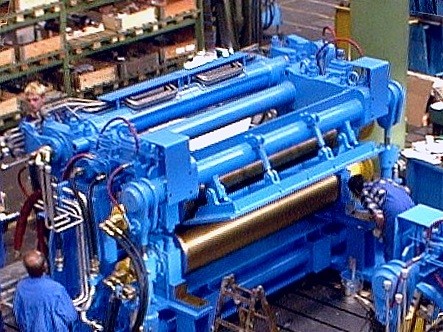

STECKEL CUTTING MACHINE

STECKEL FACTORY VERTICAL APPLICATIONS

Single-stand Steckel mill is now mainly used for hot production of stainless steel strips and special alloys. Since these materials are mainly produced in small batches, the flexibility of the plants is particularly advantageous for these applications. Depending on the product spectrum, the factory capacity ranges from 100,000 to 600,000 tons / year (without raw rack).

TECHNICAL DATA

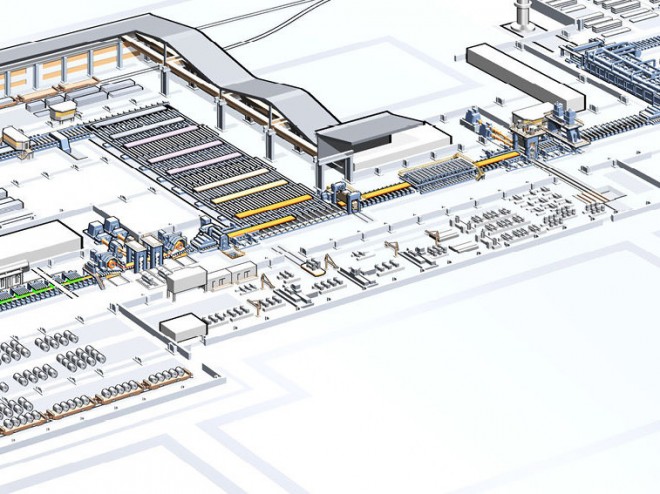

TWIN-STANDEL GENERATOR

A Steckel Mill generator combines Steckel technology and parallel coils. This type of mill gives you the ability to produce high quality hot strip on Steckel mill with production speed from 1.2 million tons / year (no roughing) or 1.8 million tons / year. with coarse grinding machine.

TECHNICAL DATA

STECKEL PLATE / PLATE

Our Steckel / Plate factory produces hot plates and strips in one line. It is the crop that guarantees the highest flexibility to adjust your production capacity according to market demand.

The production of hot plate and strip can be made either on a single Steckel mill or with a combination of a plate mill and a Steckel mill. The SMS group has successfully implemented both types of concepts.

TECHNICAL DATA

TECHNOLOGY

STECKEL LOOPER

Steckel welding machines allow higher rolling speeds to produce hot strips.

MORE INFORMATION

TABLE CAN BE COLLECTED

The rollers below the steckel furnace can be retracted ...

MORE INFORMATION

CVC ® WITH STECKEL STATION

Our stand-up steckel is equipped with CVC® plus ...

MORE INFORMATION

SIEFLEX ® HT - HIGH POWER CAPACITY

Our SIEFLEX® HT gear shafts drive the drive ...

MORE INFORMATION

SMS FREE SHIPPING

The enormous torque of the SMS can transmit up to 40% of torque compared to regular sanding piles.

MORE INFORMATION

HANDLING SYSTEM

The cooling strip is an important metallurgical process in ...

MORE INFORMATION

LÀM MÁT TẤM

Hệ thống làm mát bằng tấm của chúng tôi đảm bảo sản xuất hiệu quả về chi phí của nhiều loại thép.

THÊM THÔNG TIN

LẮP TẤM

Ngày nay, nhu cầu của thị trường đối với các tấm nặng với độ phẳng tuyệt vời và áp suất dư thấp.

THÊM THÔNG TIN

TÀI LIỆU THAM KHẢO

Chi nhánh thép đặc sản Bảo Sơn (BSSB), Trung Quốc

THÊM THÔNG TIN

Outokumpu không gỉ (Avesta), Thụy Điển

THÊM THÔNG TIN

Thép Maghreb, Ma-rốc

THÊM THÔNG TIN

Outokumpu không gỉ (Tornio), Phần Lan

THÊM THÔNG TIN

Sơn Đông Taishan, Trung Quốc

THÊM THÔNG TIN

Tập đoàn Sắt & Thép Sơn Đông Rizhao, Trung Quốc

THÊM THÔNG TIN

Siderúrgica Nacional, Venezuela

THÊM THÔNG TIN

HỆ THỐNG ĐIỆN VÀ TỰ ĐỘNG HÓA

HỆ THỐNG ĐIỆN VÀ TỰ ĐỘNG HÓA

Hoạt động và Hình dung

Vai trò then chốt của yếu tố con người

Các trạm kiểm soát được thiết kế theo thiết kế của chúng tôi hỗ trợ các hoạt động của nhân viên điều hành của bạn. Bao gồm ở đây là hệ thống HMI mới của chúng tôi hướng dẫn họ thông minh thông qua quá trình này.

THÊM THÔNG TIN

WearComp ® đang tự bôi trơn.

PRODUCTS AND SOLUTIONS (GENERAL)

X-PACT ® AUTOMATIC CONTROLLER

The best results for rectangular plates

More information

X-PACT ® CAMBER is FREE

The control system for rolling and rolling is not abrasive in the grinder

More information

X-PACT ® COILER CONTROL

Control system to ensure product quality in the winding process. (single row, top two ends)

More information

X-COOLING SYSTEMS COOLING CONTROL

Temperature control throughout the strip length

More information

X-AGREEMENT® CROP PREPARATION

Improved process stability and reduced cobbles in plant finishing

More information

X-AGREEMENT ® STRUCTURE OF PROPERTY

Online and offline calculations of particle properties such as particle strength, tensile strength, elongation to fracture, material structure

More information

X-PACT ® MILL STAND CONTROL (TCS)

Technical Control System to ensure the highest product quality (HGC, WRB, IRB, CVC ®)

More information

X-SCHEDULED SYSTEM (PSC ®)

Score system set for each pass according to the parameters and limitations of the current process

More information

X-ZONE® COOLING CONTROL SYSTEM

Temperature control throughout the sheet length

More information

X-TERMINALS ® OPTIMIZED CUTTING

The best cut to produce finished panels

More information

X-PACT ® PLATE LEVELER CONTROL

Optimizes the modeling point calculation for increased flattening efficiency

More information

X-TILE® CONTROL AND ROOM CONTROL (PFC)

Highest product quality in striped geometry

More information

X-PACT ® PROFILE, ROUND AND ROOM (PCFC ®)

The physical process model calculates the best settings for the CVC® plus actuator

More information

X-PACT ® STECKEL LOOPER

An electromechanical package for steckel mills

More information

X-TERMINAL ® THERMOMETER

Process temperature model to accurately determine the rolling process

More information

X-TREATMENT® WIDTH CONTROL

Improved process stability due to better band guidance

More information

SERVICE

SERVICE

https://www.sms-group.com/fileadmin/_processed_/a/f/csm_N-SMS0839-110r_Consulting_Training_5a05279410.jpg

Consulting & Training

Build on experience

However, not just a service partner for your machines and machines, SMS groups are also available for your employees. Moreover, you can participate in the standard and customized training programs designed for you by our SMS TECademy. That assures you to strengthen your capacity as a factory owner.

MORE INFORMATION

EDOC

Document Number: The first step to a smart factory

More information

EMERGENCY - EMERGENCY SERVICES

To easily identify defects and malfunctions and quickly initiate measures to eliminate errors.

More information

CHECKING DEVICES

Regular inspection and maintenance is the basis for effective protection of your equipment.

More information

GENIUS CM

Genius's state-of-the-art surveillance system includes an online tracking system and modular design.

More information

HIGH PRECISION TO FACTORIES

The Sieflex® HT sprocket is the key to greater torque and torque.

More information

LONG-TERM MAINTENANCE SERVICES

The SMS team offers you full range of services along the value chain, while you can focus fully on your core competencies.

More information

MAINTENANCE TOOL - IMMS

Integrated Maintenance Management System (IMMS) ensures efficient and economical maintenance.

More information

SERVICE FOR X-ROLL® BENCH OIL

X-Roll ® Oil Bearing - A basic part of modern rolling technology

More information

HEADSET FORM

Healthy slippers are larger cuts for each pass and longer shelf life.

More information

WEARCOMP ® - A NETWORK IN MAINTENANCE MANAGEMENT

Lubricating grease is a costly and time consuming process. Components made from WearComp® patented compound material are self-lubricating.

More information