Supplying equipment and transferring production technology

Cung cấp thiết bị và chuyển giao công nghệ sản xuất

ELECTRICAL MANUFACTURING

Nothing succeeds as the success with ARCCESS ® technology from the electric furnace technology from the SMS group. All components are dedicated to cutting down the cost of electric steel production. This makes your investment pay off even faster.

ARCCESS ® EAF Technology

THE SOLUTION FOR YOUR SUCCESS

Nothing succeeds as the success with ARCCESS ® technology from the electric furnace technology from the SMS group. All components are dedicated to cutting down the cost of electric steel production. This makes your investment pay off even faster. We build on decades of experience in electric furnaces, metallurgy, and processes that are optimized to provide you with the most cost-effective solutions. ARCCESS® is a high performance powerhouse. That's because they come with future-oriented oxygen injection technology and oxygen injection technology. That gives you high productivity with low production costs.

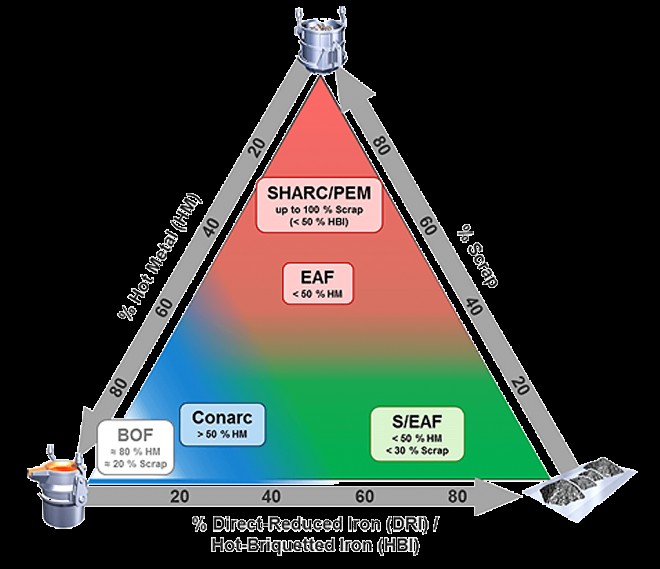

Modern steel plant with flexible material input

A solution for all the materials used in the production of electrical steel

HIGH PROFESSIONAL

The leading factory logistics

Modular furnace design

Furnace shell

Design the best control panel

IMPROVING THE KNOWLEDGE

Highest efficiency with efficient spraying, burning and oxygen technology

Energy efficiency

Electrode control system

Slag method

Arccess ® EAF - furnace

Success based on experience

We have built a valuable experience from more than 100 years of development, construction and operation of electric furnaces.

That's why, with nearly 1,400 electric furnaces in both new construction and renovation projects, the SMS group is among the world's leading suppliers.

THIS IS THE ONLY POWER TO OUR WEB SITE:

Modular design

Grouped components are standardized

Low maintenance level