Nhà máy sản xuất, (Sữa & Pho mai) – Germany

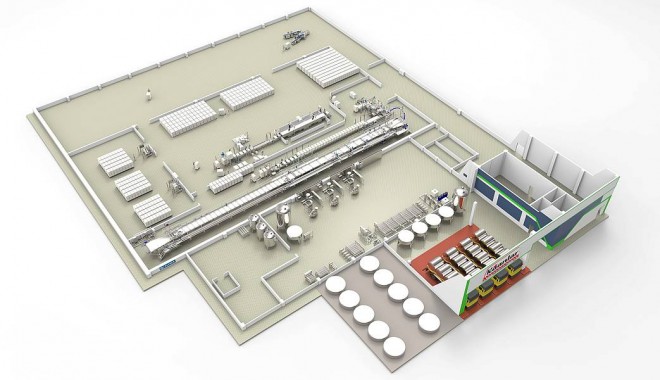

Factory, (Milk & Cheese) – Germany

Your partner in the field of process technology and production installation

Together with LTH Dresden, ALPMA has been supplying innovative installations to the food industry worldwide for over 20 years. We are experts in pre-dairy processing for dairies and continue to process sweet whey and acid into high quality whey protein products.

We plan and manage the installation of specially designed milk to suit the requirements of customers such as:

Milk and whey receiving system

Production line of fresh and sour milk products

Tank

Pasteurized milk, bleach, sterilization

Milk standard for fat and protein content

Warm milk

CIP installation and heat transfer system

Pipe system

Cream treatment

Prepare wash water

Preparation and quantification of cultures.

Project management and production of membrane filtration equipment including complete control and adjustment technology for the following applications:

Segmentation and whey concentration

Standardize / output serum casein

Sterilize milk and whey

Production of cottage cheese and cream

Bacterial stability of salt water

Filtering solutions from biotechnology

Special applications in the food and pharmaceutical industries.

The following techniques are used for this:

Micro Filter (MF)

Ultrafiltration (UF)

Nano Filter (NF)

Reverse Osmosis (RO).

Many pilot installations are available to assist in layout and optimization of industrial buildings as well as for trial purposes!

The ALPMA CreamoProt process allows you to use your own valuable whey protein as follows:

Replace casein in your product with less expensive whey protein

Replacing milk fat with whey protein is less expensive

Increase the water binding capacity of the product

Increase output, save costs, improve the quality of your product!

The production of ALPMA CreamoProt can use both fresh and sour whey and is being used on an industrial scale throughout the world. It provides an interesting and innovative view especially for light and healthy dairy products.

Area of use:

Cheese soft and yellow

Cream cheese

Desserts and quarks

Ice cream, food

ALPMA develops and implements exciting economic applications for the direct use of whey liquids, byproducts of the cheese production process.

Example of use:

Use concentrated whey protein liquid (WPC35-60) for fermented milk products. Concentrated whey protein concentrate with ALPMA CreamoProt

Whey surfing and sterilization. Produce WPC and WPI from whey / whey ideal

Use whey protein concentrates with ALPMA CreamoProt process

Demineralisation of fresh and sour whey.

Whey concentration by reverse osmosis (RO).

Your partner in cheese production

ALPMA, your partner in cheese production, builds installation facilities to produce soft and golden cheeses, using some of the best technology in the world. The only principle of continuous cheese production is built and perfected by ALPMA. Installation technology, control technology and our technology expertise - all from one company!

ALPMA designs and manufactures dairy equipment for a variety of cheeses and sizes.

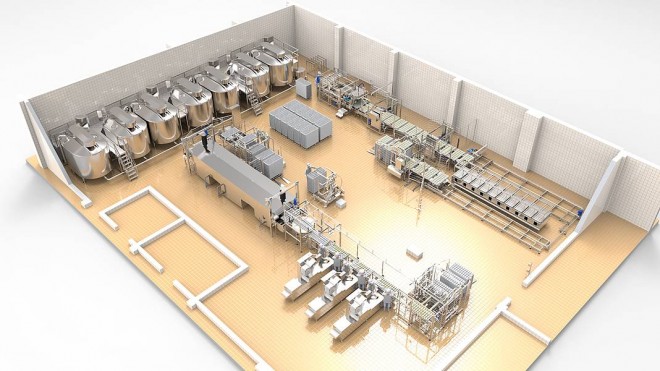

Industrial installation - Continuous cheese Production over 1,000,000 liters / day

Automatic milking, the highest degree of precision with a balanced ratio of technology and continuous conditions during ripening will ensure superior productivity and hence the success of industrial cheese production. friend.

Medium installation equipment - Continuous cheese Production of up to 100,000 liters per day

High flexibility, variety of cheeses and innovative adjustment are features of today's average dairies. Yogurt preparation is either continuous or continuous using modern coagulators or in traditional cheese barrels.

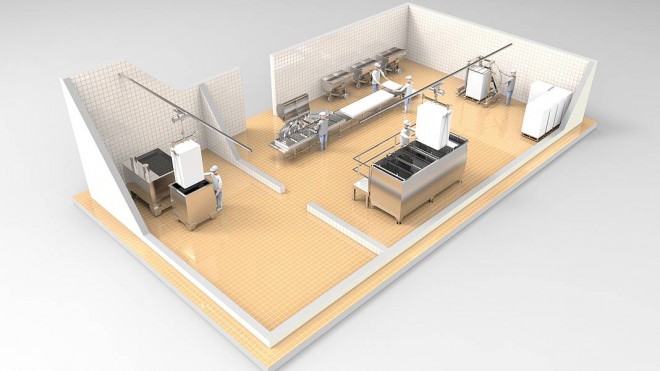

Small Installation - Continuous Cheese Produces up to 10,000 liters / day

With cheese tanks of 400 liters, efficient production circuits can be created. Ideal for processing milk up to 10,000 liters / day and for all types of soft cheese.

The art of yogurt preparation is decisive for the productivity and quality of the cheese. ALPMA provides the optimum system for preparing small batches to large installations with more than one million liters per day.

Regardless of whether the batch system or installation is fully used - ALPMA always offers the best solution!

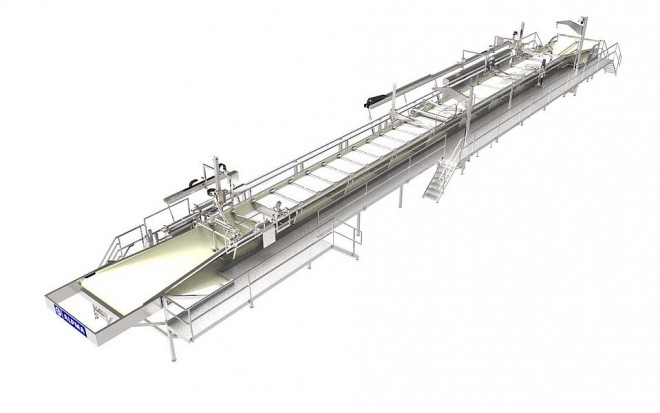

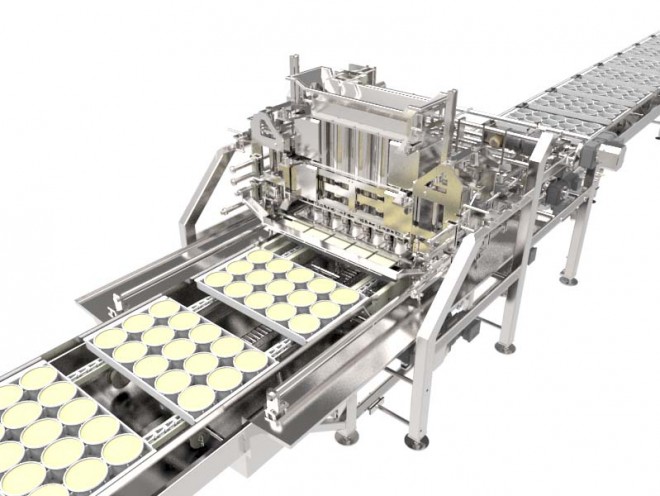

Coagulator 2000 - to produce soft cheese and yellow cheese

Coagulator 2000 and 2000 S continuously operate up to 45,000 liters per hour. Unique ALPMA Coagulator technology ensures superior quality and productivity by cutting and preparing delicate yogurt.

Bassine System - to produce soft Cheese

The frozen milk processing system with Bassine barrels can be moved to small and medium production facilities. Depending on the room size, can be flexible layout.

Cheese Curd Vat KBA - to process small amounts of milk

Portable and tiltable, freeze-drying equipment, equipped with cutting and machining tools, are precision-tuned, flexible and ideal for drilling.

You can use KBA to create a production circuit that can handle the amount of milk processed by medium-sized plants.

Dilution is a task that needs to be done exactly 0014

The quality of the curd and segmentation technique determines the quality of the cheese at an early stage. It is not easy to correct the deviation and directly affect the weight, consistency, shape and quality of the cheese.

ALPMA has developed differentiated systems for a wide variety of cheeses, which are tailored to a variety of requirements.

MR 0015 split

High power sharing, distinguishing itself with exceptional accuracy.

In single or multiple lanes, there are up to 24 compartments, either filled or pumped. Hygienic CIP equipment ensures optimum MR performance:

Lightweight

Highest flexibility

Maximum power level

The best sanitation

Trimming ABP

Automatic battery division for soft and hard curd types with high power. Each division cycle is filled with a complete block.

ARP-T split

Automatic division for medium weight cheese, such as large cakes and soft to semi-hard cork.

AFE charging device

Half or full filling equipment automatically replenishes the correct amount and replenishes the yogurt's starch and safe collection of yogurt while ensuring no loss of milk.