Factory, Glass - Italy

Equipment supply and technology transfer - Italy

GLASSWARE

Based on three decades of operation in packaging, in the early nineties Zecchetti developed the first computer for the hollow glass industry, with a great contribution to the efficiency gained by introducing the innovations of the column palletizer. Replace star chart or portal machine. The experience gained from the installation of hundreds of lines and the cooperation with leading multinational glass mills has enabled Zecchetti to develop machines and accessories for pallet handling and handling. Operability allows customers to have a single vendor to build the entire production line.

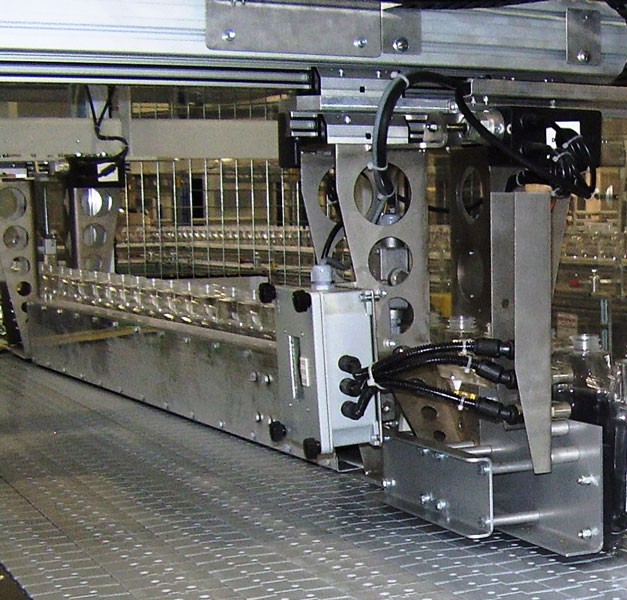

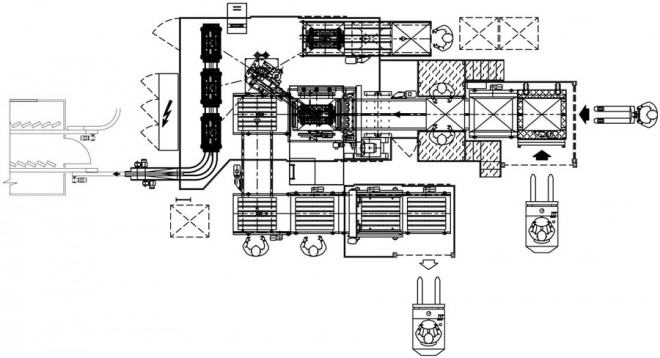

COLD CONVEYORS FINAL

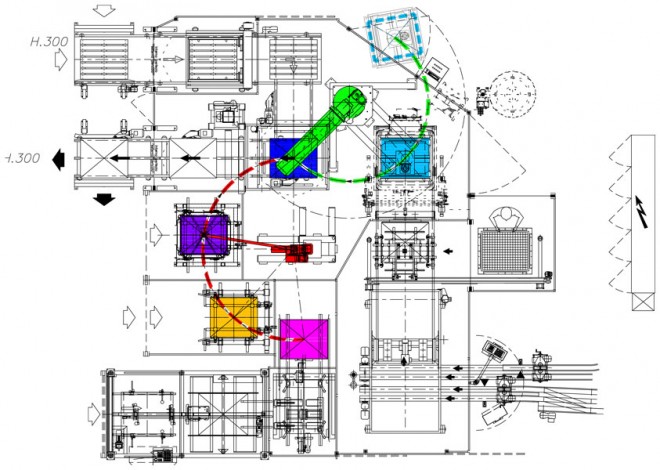

SOLUTION FOR CONTAINER TYPE, IN ONE AREA

Someone who keeps the refrigerated conveyor just an entire gears and chain can even be reached with commercial modules. Everyone knows that Glass-Works is fully aware that every one meter of secret secret lines is important to ensure efficient operation of the system. Needless to say that only hard experience in this area can develop new solutions and build knowledge to help find and apply solutions that best fit the needs of customers such as:

types and mixtures of containers to be treated;

line speed;

type and speed of the test machine;

available space;

auto-level requirements;

Previous experience of glass;

open for future needs etc.

Zecchetti knows how, acquired through decades of experience, allows to choose the best solution to make each cold end line in line with the needs of their customers.

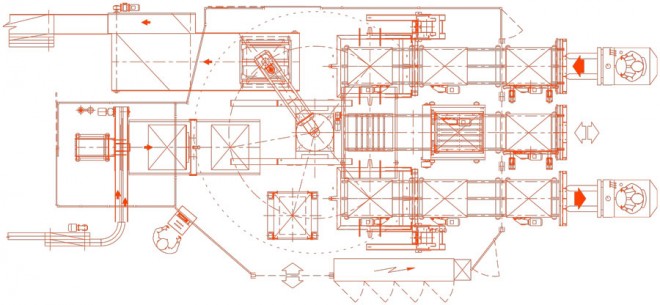

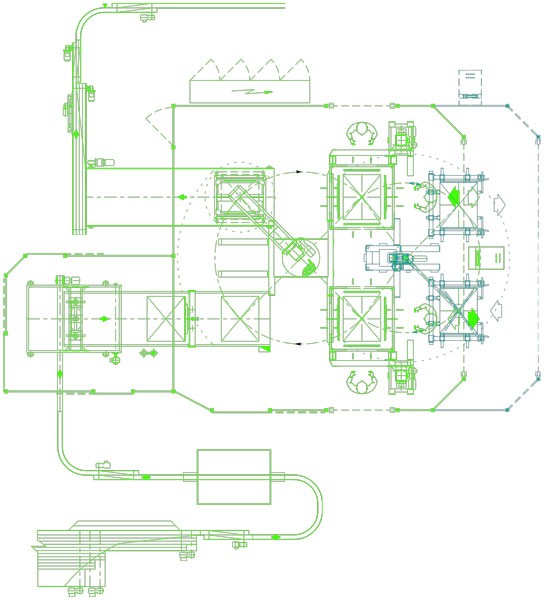

SOLUTION FOR ORGANIZATION AND DECORATION

COMPACT AND FLEXIBILITY

Thanks to the range of palletizers and depalletizers developed for 50 years of long operation Zecchetti can provide exciting solutions for the process of arranging and decorating. In particular, the versatility and modularity of the rotary column allows for the creation, with a single machine, of multi-functional islands, extremely compact and functionally to queue up and depalletize. Automation levels can also be adjusted according to specific needs without having to upgrade automation in the future. These features make Zecchetti the ideal solution for the sorting and decorating process.

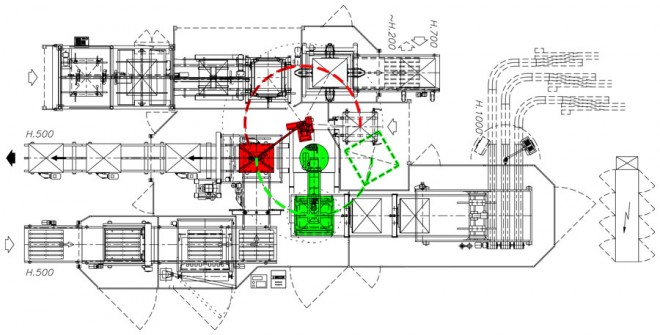

T-PAL MISSION PURPOSE PURPOSE

SPACE MAKES NO MORE THAN UP

The type palletizer type online. T-PAL represents an alternative to rotary column machines and of course is of equal value. A static column supporting a horizontal beam is the core aruond that the machine can be constructed according to the available space, the required degree, required palletizing mode / s.

The T-PAL module is ideal for short, medium and long term investments.

R-PAL

A ROTAL COLUMN SERIES EXTERNAL DEVICE FOR ONE SELECT, MAX ERROR D FNG Closing Machine

pallet type rotary column. R-PAL MPH (Multi-purpose Head) is the highest expression of important features such as flexibility and accessibility. Its modular design allows it to fit, even in the future, with any type of layout, production and article. Actually, it can make both operations in "scan" mode and in "pick and place" mode with the advantage that the decision can be made at any time in the future, not least. must be at the time of purchase. The three-axis operation design, which was born 30 years ago and was made with the Zecchetti rotary column, has been developed over the years to increase reliability, flexibility and performance. Its success has been enhanced by more than 1000 units in operation worldwide, of which 300 are in glass mills.

Stacker

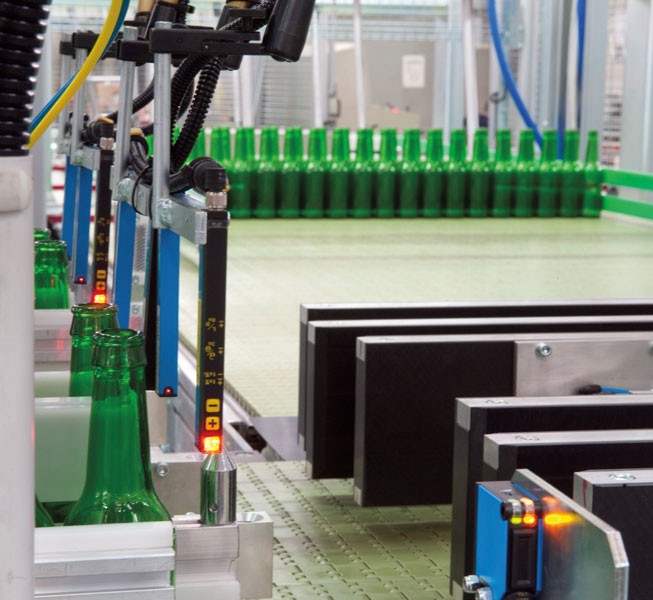

HANDLING ANY CONTAINER, WHETHER SHAPE

Thanks to his experience "in this field" Zecchetti knew that piling and more general layering stages were probably the most important production of pellets. Indeed, this is the first area in which shaped containers have to be precisely and precisely prepared to reach all the "infinite" palletized samples that the manufacturing plants will produce. meet the needs of customers. For this reason, Zecchetti offers a broad and advanced range of speed, number of feeding lanes, specialized equipment for special shaped containers, and automation options. The ultimate goal is to have the best solution to fit the specific needs of each customer

EQUIPMENT DEVICE - SPECCIAL SYSTEM,

CONTRACT SOLUTIONS SOLUTIONS FOR GLASSWARE

50 years of experience in the manufacture of automatic machinery allows Zecchetti to introduce a range of devices that can meet all the needs of the glass cold zone and much more. Zecchetti can provide turnkey lines, from the Lehr waste to the warehouse, even in the case of special requirements. Namely all equipment required by the glass factory for their specific processing of empty and full pallets. Furthermore, thanks to the "Zmagazzini" Shipping Division, Zecchetti can also propose automated solutions for full pallet storage and loading them into trucks. High benefit is also the Auto Vertical stand, which is used for "good order" storage, in space optimization and in the way of protection of spare parts, changing parts and mold IS.

SPECIAL TYPES OF SPECIAL OFFICE SPECCIAL SPECIAL

With containers in shape, which can be easily lined up, or in the case of closed environments, Zecchetti proposes a number of solutions using their own robots or robots. The use of actual robots can perform some operations by means of the same reception system serving several stations, thus minimizing space and allowing the insertion of different class separators. The long experience in automatic processing allows Zecchetti to research and develop the right solution that suits the needs of its customers.

PUMP PACKAGE IN CARTONS / SHRINK WRAPPED TRAYS

Package includes:

Continuous flow dividers for stock preparation;

Paker for tray / carton filling

Shirink-Wrapping Machine for Bundle Preparation Finally

Based on the required speed, various system versions are available

IMPORT AND EXPORT IMPORT AND EXPORT CO

In order to complete the automatic lines, a number of modules for pallet movement are required. It is important that these conveyors are designed to fit all existing pallets and to meet the specific needs of glass works. In fact, it is important that these conveyors go to the changing station in a smooth and smooth manner. Only in this way will the load be protected by preventing the collapse of the container, especially the external parts, from damaging the entire pallet at the expense of product quality. It is extremely important that their design makes them well protected against the creation of debris, so that they are crossed by operators when necessary and made them shielded by attacks. of FLT. Likewise, the type and degree of protection of the conductor is required to avoid the risk of damage in the event of a normal fall. Many solutions are available to meet every need:

Simple or double conveyor (2-3-4-5 and 6 lanes); Guide roller with many notes; gravity roller conveyor;

90 ° transfer unit side including roller + chain or chain + chain for any demand and any load; roller or roller chain; roller or lever to change the level; Higher level conveyor.

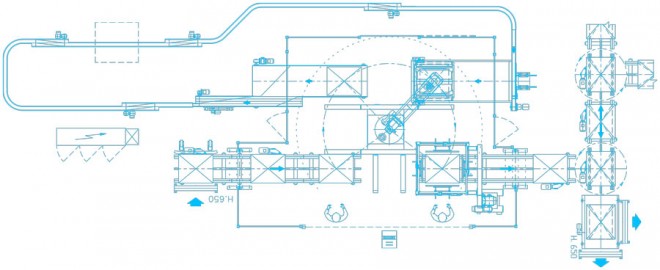

HOW TO TRANSFER

In general, a cold end system needs to automatically charge and extract the empty and full pallets to and from the different pallets, towards the brick or loading dock. To carry out these activities by keeping the access road free, often used by Linear Shuttle cars. The reliability of these shuttles is as important as that of the palletizers, if not better; The entire glass production operates on such devices. The experience brings Zecchetti the best and most advanced solutions: positioning through laser systems, powering cabinets on the bus, WI-FI signaling, and accident prevention through PLS protection. . Construction strips include:

1-2-4 pallet stations; with or without leading newspapers; with or without access.

HOODING / SHRINK-WRAPPING OVENS

This is the most widely used system in glass construction to isolate pallets and products from environmental contamination and weather events while ensuring maximum container stability during the process. shipped to the end customer. The full pallet is lifted and covered in vapor with a sealed polyethylene film (80/200 micron) sealed on the bottom of the pallet. The narrowing of the tubular tube until product contact and complete package of pallets is achieved by using natural gas or propane burners and emits hot air directed over the entire surface. In case a film has been placed on a blank pallet, this film is welded to the bag thereby creating a completely sealed environment. After cooling, the housing becomes rigid to ensure maximum stability for the pallet. Many versions are available with one or more film roll tubes of different formats. This means it is possible to wrap two different sized packages, which are also randomly fed, as the machine automatically selects the coil in the package. Zecchetti can include in their lines Ovens of major brands such as OMS, THIMON, etc.

EQUIPMENT IMPORT AND EXPORT BY PHAM TANG

In some situations, and usually on previously mounted pallets, load stabilization is accomplished by wrapping pallets with different twists of polyethylene tensile. In addition, conventional topcoats are also included to protect the pallet from weathering agents. Zecchetti can be included in the line of Packing Equipment of the major brands such as Robopac, OMS, Strapex, etc.

LAPTOP CLASSES (on the format sheet) Each Zecchetti palletizer can be equipped with different strapping systems that can be placed in different zones, suited to the needs of the customer and in different situations:

belt set at the top of the pivoting table version or fixed version);

The strap is placed in the middle of the table next to a cup or far away.

Zecchetti can include in their line strappers of major brands like: OMS, Strapex, Endra, Signode, Delonca, Etc.

TRAIL LABELING

A solution for labeling trays from the Tray. Labels often display information about the pallet being formed. Some options are: label size: A4, A5, etc.; Label position: on one or more tray faces.

RECORDS LIST OF OTHER MATERIALS

Various solutions are also available for labeling pallets that have been completed.

Some options are: label size: A4, A5, etc.; label position: on one or more pallets; at a constant height or change;

Labeling: before or after palletizing, with tracking information.

EXPORT MACHINERY

The Zecchetti fastening machine can fit all the requirements for the creation of trays or special masks to serve a palletizer or work as part of the popular centralized system for other palletizers. together. A variety of adjustments are ensured, for the tray size and for the lid size. Some versions of Tray Formers are available as:

Closed loop: by glue, by needle, by clicking on the system;

change format: hand, manual wheel, auto;

Configuration: moving wheel, fixed with self-loading pallet empty, with automatic loading; Speed: up to 5 trays per minute.

ALLET HOR Vertical Stack

A full pallet strapping system can be recommended, both vertically and horizontally. It is possible to put the strapper either at the palletizer outleed or at a common area to serve a few lines. In either case, you can decide which pallet to use and how. Some options for horizontal straps:

that pallet to the strap; that layer to strap etc;

In the case of vertical straps, the high pressure head to protect against the straining time of the strap is always included. Some options for vertical straps:

the number of straps per pallet;

CONTRIBUTE.

Zecchetti can include in line strappers of major brands such as: OMS, Strapex; Cyclop, Messersì and so on

AGV (Automatic Vehicle Coach)

In order to complete the automation of glass plants, Zecchetti can extend their supply to automatic pallet warehouse, through the supply of AGV or

LIST OF LEADING PRODUCTS / LINES

Checking their pallet quality and makeup is essential to ensure the palletizer's performance and quality of finish.

To perform these steps in automatic mode, Zecchetti suggests their versatile islands can:

SORT

Automatically remove the film by hot air blower;

Clean pallets with brushes;

Determination of moisture and color;

Check the integrity of the pallet;

Check the pallet perimeter

IDENTIFIABLES CATEGORIES:

1) pallet first choice;

2) Pallets have "peak";

3) "out of shape" pallets;

4) Pallet is repaired;

5) The pallet with "outside height and is repaired;

6) Pallets must be removed;

7) Pallet with unacceptable moisture content;

DRESS

Film insert; miniature, glue or film editing with key items;

insert class table; Glue or glue the adhesive pad

PALLET warehouse automation Reduced warehouse area, total number of interfaces to production and control systems and automation of entire pallets and loading dunnages make Zecchetti's automated warehouses an ideal solution. for glass manufacturing plants. Rapid return on investment is even more interesting in situations where space availability decreases dramatically, especially in the process of expanding the facility. This system, in addition to conventional locations for cargo handling, is expected to be operated and transported by forklift trucks, which can be completed with a fully automated truck loading system.

Vertical stand (with tray)

One major problem of glass manufacturing plants is the storage of all accessories for different production equipment such as spare parts, parts changes, molds, or consumables. With the Zecchetti vertical automated warehouses with trays that can protect and monitor all stored materials by identifying available quantities, availability quantities, organizational needs, value of goods. They store, regardless of their location. By fitting the trays, storage and molding can be done in ideal conditions, and the trays can be placed directly during preheating. Thanks to its versatility in size and construction, Zecchetti's vertical automatic warehouse is the ideal solution to solve all problems of space, security, protection and efficiency of interior storage. glass.

All the equipment is designed and designed according to the needs of the glass factory thanks to Zecchetti's expertise in hollow glass.

Scalability automation for all departments of the company.

Product quality is guaranteed at every stage by eliminating human error.

Fast return on investment.