Factory: ammonia, urea ammonium nitrate, melamine - Germany

Germany: Supply equipment, technology - EPC contract

FERROSTAAL INDUSTRIAL PROJECT

Ferrostaal Industry Project is an international project developer and EPC service provider in the field of industrial plants, especially the petrochemical, wind and hybrid energy industries as well as the projection solutions. shining. Project development, finance and industrial plant construction are the main strengths of Ferrostaal IP. In the global MPC group, Ferrostaal IP has access to a global logistics network, with more than 85 years of experience and extensive international references for all industrial plants. Ferrostaal's main office is located in Essen, Germany, while the largest warehouse is between Rotterdam and Antwerp. Ferrostaal IP pursues a holistic approach to assisting its clients in all phases of the project. From concept to feasibility study through partner selection and technology, Ferrostaal IP offers a range of services to its clients engaged in collaborative projects and financial closures. Ferrostaal IP will monitor and coordinate all processes to ensure that industrial plants are completed on time and on budget.

Ferrostaal has specialized in the construction of petrochemical plants

Ferrostaal & Partners has built a factory complex to produce ammonia, urea ammonium nitrate (UAN) and melamine

Ferrostaal has a long history of working with Methanol Holdings Trinidad Limited (MHTL) and its predecessors since the early 1990s. Ferrostaal has built factories to produce two synthetic gas products on Trinidad: methanol and ammonia. In 2006 the company built four methanol plants for the MHTL and two ammonia plants - including the M5000, which at that time was the world's largest methanol producer. As a result, MHTL became the second largest methanol producer in the world.

Then, Ferrostaal built the AUM complex with an investment of $ 1.6 billion. The plant comprises a total of seven individual plants and three sub-assemblies, producing ammonia, ammonium nitrate (UAN) and melamine. Production is primarily aimed at markets in North America and Europe. With the implementation of 13 petrochemical plants in Trinidad & Tobago, Ferrostaal has contributed significantly to the ongoing industrialization of the country by becoming a shareholder in the MHTL.

About Methanol Holdings Trinidad Limited:

Before the complex business of AUM MHTL focused solely on methanol production, the MHTL currently produces 4.1 million tons of methanol per year

This company is the largest methanol provider for North America. As of 2010, MHTL also produces ammonia, UAN and melamine that make it a multi-product petrochemical company.

The company's M5000 plant is the largest methanol production plant in the world with a production capacity of 5,400 tons per day.

Building a petrochemical complex

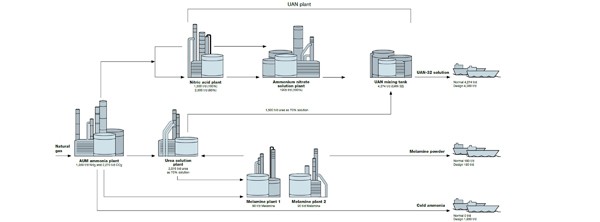

In order to harvest more efficient Trinidad & Tobago liquefied natural gas, the AUM complex is said to purify natural gas for ammonia, ammonium nitrate (UAN) and melamine. The construction period for the entire petrochemical complex was determined to be 34 months. The first part of the plant, in which ammonia was produced, was completed and ready to start production after 28 months. Construction of the plant's second factory, uranium and ammonium nitrate plants and two melamine plants was completed in 2009.

In mid-2010, Ferrostaal - along with a number of technology partners - identified seven separate petrochemical plants to produce fertilizer and melamine. As the main contractor, Ferrostaal is responsible for concept and project coordination as well as project management for the entire complex. From the implementation of the technical basis, delivery of components and construction. Because Ferrostaal is also an investor, it has an additional interest in the profitability and efficiency of the complex.

The AUM complex is the first downstream petrochemical project in Trinidad & Tobago and the entire Caribbean. In addition to the implementation of the AUM Ferrostaal complex as a shareholder of MHTL, we also lead the development of projects for all MHTL projects including. M5000 and facilitates the structure and arrangement of the loan from KfW IPEX Bank with the coverage of EULER-HERMES.

The AUM complex produces three main products: (i) UAN-32 solution, a direct liquid direct fertilizer, (ii) melamine, white crystalline powder used in laminates, wood adhesives and surface coatings; and (iii) cold ammonia, which can be used as fertilizer or as a precursor for further downstream processing. The first step is to screen natural gas in the AUM ammonia plant for ammonia and carbon dioxide. Both were converted into urea solutions in the urea factory.

The AUM ammonia plant also supplies the UAN ammonia plant, producing the first nitric acid from ammonia and oxygen in the atmosphere in the nitric acid plant. Nitric acid is then converted to ammonium nitrate solution in the ammonium nitrate plant. The solution is then mixed with urea solution from the urea plant to produce the final product, UAN 32-solution. In the second step, the AUM mixture produces melamine in the second plant section using pure urea. The melamine plant transforms urea under pressure and temperature into melamine. To clean the reaction products ammonia and carbon dioxide are added to the process in small quantities.

Số liệu quan trọng:

| SỐ CÂY RIÊNG LẺ: | 7 |

| ĐỊA ĐIỂM THỰC VẬT: | Điểm Lisas, Trinidad |

| LOẠI HỢP ĐỒNG: | EPC |

| KHÁCH HÀNG: | Công ty TNHH Methanol Holdings Trinidad Limited (MHTL) |

| ĐỐI TÁC: | Eurotecnica (công nghệ và kỹ thuật), KBR (công nghệ và kỹ thuật), Toyo (công nghệ và kỹ thuật), Uhde (công nghệ và kỹ thuật), MHTL (khách hàng) |

| CÔNG SUẤT NHÀ MÁY UAN PHÂN BÓN: | 4.300 tấn / ngày |

| CÔNG SUẤT NHÀ MÁY MELAMINE: | 180 tấn / ngày |

| TIÊU THỤ KHÍ TỰ NHIÊN (TOÀN BỘ PHỨC TẠP): | 80 mmscf (triệu feet tiêu chuẩn feet) mỗi ngày |