Factory & Equipment, Beer & Wine - Switzerland

Nhà máy & thiết bị sản xuất, Bia và Rượu - Switzerland

Brewery and distillery products

The ideal base for brewing and spirits.

Cooking and distilling are highly skilled processes that require extensive knowledge and years of experience to master. As the world's leading technology provider for the grain processing industry, Bühler can provide customized solutions for optimal material handling and assist you with every step of mushroom production. Provides solutions from salty and cereal foods, grain preservation, transportation, cleaning and grading, through grain preparation by peeling and color classification, even when milling and whole grains. other nuts.

Bühler's milling machine and hammer ensure that the product is milled and exactly the right size for the particular grain.

Bühler offers the latest brewing technologies and solutions

morale. The optimal processing of the grain and its processing to produce high-quality mashes is the basis for efficient brewing. Bühler is your partner for solutions from raw to friction products and can assist you in optimizing the entire brewing process.

Bühler offers the latest brewing technologies and solutions

morale. The optimal processing of the grain and its processing to produce high-quality mashes is the basis for efficient brewing. Bühler is your partner for solutions from raw to friction products and can assist you in optimizing the entire brewing process.

Clean reliable.

Reduces wear and tear in the system.

Beans and malt usually contain pollutants such as seeds, rocks, soil, and other types of foreign bodies. With our machines, you get the raw material, not contaminated.

Combined MTKB with four cleaning functions

Effective Grain Cleansing: Sorting by weight, screening fine and coarse grains, removing stones, and aspirations of light

GrainPlus LAGA screening machine to remove contaminants

Optimal cleaning of the grain by light separation and rough fractionation and separation of metal parts with optional magnets.

MTSC Destoner to extract ice and glass

Separation of heavy components from continuous product lines with excellent resolution.

Low energy consumption thanks to integrated air. Circulation system.

Optical classification with SORTEX

Camera-based control and separation of defects and contaminants such as fusarium, burnt barley, insect parts, or ergot black.

MZAH flow balancer for exact mix product

Gravimetric, a continuous dosage of products for the production of high precision precision cell product mixes.

Strong magnets to resist the iron in the process

Removing iron parts from machine-made products protects reliable machinery and increases system availability.

Homogeneous moisturizing products.

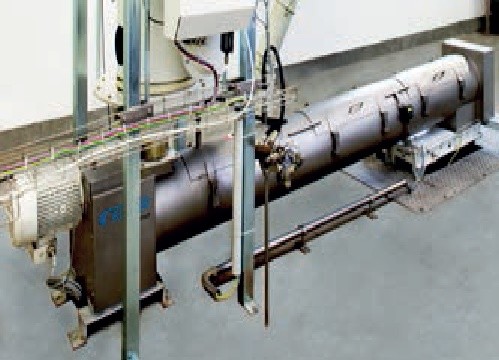

Time is short, accurate time of use. The modern tunnel system achieves top lautering speed whether you are using wet or dry grinding. Dry grinding conditions for maximum yield in high husk volume, increasing cost efficiency.

Strong hammer factory.

For maximum use. For use with jam filter systems, for coarse grained applications and for distillation plants, Bühler provides both horizontal and vertical hammers to achieve granu- lation. Your system needs.

Fast, competent customer service.

Support throughout the service life. Your satisfaction has top priority. That is why Bühler's staff at local offices on the site are ready to respond quickly and at all times. More than 1000 employees over 100

Countries participate in the needs and wants of customers, and ensure that systems and machinery are supported throughout their service life.

Effective screening and dosage. Carrying, packaging, automatic dispensing.

For microprocessor hops, the vibrovaporiser ensures the extraction of acid alpha at temperatures below 0 degrees. The mixer is fed raw material and alpha acids with quantitative accuracy, which will be processed into high quality pellets in the next step.

For the use of automated hops, Bühler offers solutions for the transport, weighing and distribution of hops into the pan.

Cơ sở lý tưởng cho sản xuất bia và tinh thần.

Nấu và chưng cất là các quy trình có tay nghề cao đòi hỏi kiến thức sâu rộng và nhiều năm kinh nghiệm để làm chủ. Là nhà cung cấp công nghệ hàng đầu thế giới cho ngành công nghiệp chế biến ngũ cốc, Bühler có thể cung cấp các giải pháp tùy biến cho việc xử lý nguyên liệu tối ưu và hỗ trợ bạn với từng bước sản xuất nấm.Chúng tôi cung cấp các giải pháp từ việc ăn mặn và ngũ cốc, bảo quản ngũ cốc, vận chuyển, làm sạch và phân loại, thông qua việc chuẩn bị hạt bằng cách lột và phân loại màu, ngay cả khi nghiền mỳ và các loại nguyên liệu hạt khác.

Chất lượng đã được kiểm chứng của máy nghiền cuộn và búa của Bühler đảm bảo rằng sản phẩm được xay đều và chính xác kích cỡ đúng cho loại hạt cụ thể.