Factories, ironworks, blast furnaces - Ytalia

Supplying equipment and transferring production technology

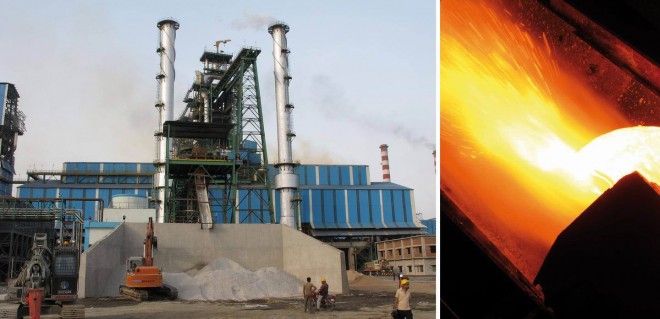

IJBF - Modern Blast Furnace Technology

BENEFIT

"Infinite" tuyere, bosh, belly, and stack campaign life> 25 years

High productivity throughout the campaign (> 3 thm / m³ wv.d)

Especially suitable for coal spraying as high as 250 kg / thm

Maximum usability

Minimum maintenance requirements

Low heat loss

Developed for operators, by operators

Specific improvement solutions for flexible customers

Plant Review for ReExcline Strategies Reduces CapEx

IJ CHARGING - Hydraulic system put the material into the furnace

BENEFIT

Lowest cost to optimize performance

Only four moving parts

Hydraulic cylinders to tilt

Inverter frequency inverter

Minimum maintenance

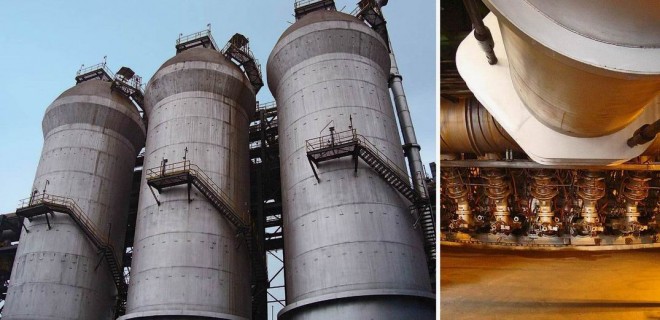

IJ STOVE - Ore Furnace

BENEFIT

Over 30 years of maximum life expectancy

Design optimizes the performance of the maximum heating system

Minimum emission

Mushroom dome for optimum stability

Dome stand alone allows for widening of the wall ring

Full stability within the operating temperature range

The partition has insulating and air barriers to ensure maximum stability and prevent short circuits

Independent inspection and testing of 100% fire resistant material

The long history of evaluations and exploration of hot break systems

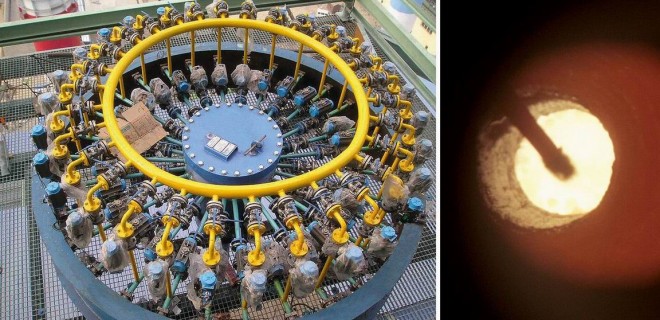

IJ PCI - Grinding Equipment Grinding System.

BENEFIT

The highest maintenance rate was over 200 kg / thm

Lower consumption of metallurgical coke up to 300 kg / thm

Recorded blast furnace efficiency up to 3.5 m / m³ wv.d

Highest availability

Most gas-to-coal ratios are the same

The most stable control through the physical principle

Minimum maintenance requirements

Most flexible for coal selection

Leading gas is optimized for downstream applications

IJ GRAN - Slag forming equipment system

BENEFIT

Simple factory configuration

No grinding equipment required

Uniform particle size (up to 3 mm)

Sand with a glass content of more than 98%

Tower condensate helps remove h2s and so2 emissions

Cooling Towers effectively removes sand and deposits

High availability (> 98%) and low maintenance

C-DRIVE - Oxygen blower

BENEFIT

Quality: continuous improvement process

Efficiency: improved mining procedures

100% availability and reliability

Performance quality is reproducible

Optimize bucket life

Advanced data management

Can be made in any existing steel plant

Can be combined with other systems, such as C-Hawk

ROI <1 year

C-HAWK - HIGH TEMPERATURE AND DYNAMIC CIRCUIT CONTROL SYSTEM IN CONVERTED STEEL MANUFACTURING

BENEFIT

Small slag treatment

Improving mining procedures

There are no consumer goods

Compact system

Maintenance free system

The ability to tilt the drive is not affected by the system

Independent control systems (non-standard systems, sliding doors or compressed air systems no longer needed)

Can be made in any existing steel plant

Can be combined with other systems such as C-Drive

ROI <1 year

C-WATCH © CLEARANCE AND POWER MANAGEMENT SYSTEMS FOR BOARDING MACHINE

BENEFIT

Safety: detect leakage in cooling circuits

Constant monitoring of water cooling parameters

Self-diagnosis system automatically checks all functions of the valve station

The independent system is completely tested

Energy saving

Usability and reliability of the system

ROI soon due to lower energy costs

ROI <1 year Self-sufficient system

Easily made at any existing steel manufacturing facility

C-SUBLANCE - SUBLANCE BASED PROCESS CONTROL SYSTEM

BENEFIT

Produce steel at the touch of a single button

The shortest cycle

Maximum factory output

Highest access rate

Minimum production cost

Minimum emission

The life of the conversion campaign is longer

Optimum health and safety