Thiết bị và công nghệ cho nhà máy sản xuất sơn – Sweden

Equipment and technology for paint factory - Sweden

Paints, coatings and plastics solutions

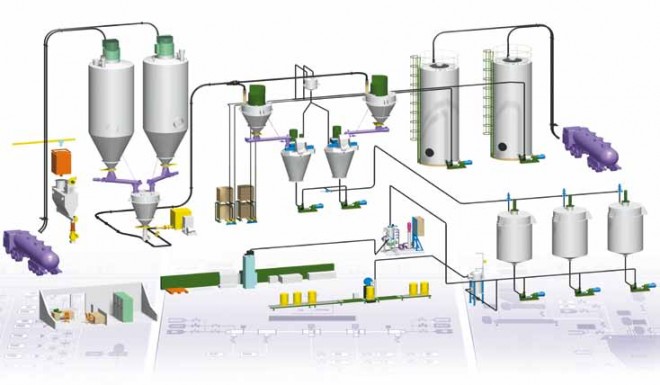

Design, install and operate complete automation units for the construction and manufacture of paints, paints, varnishes and plastics. ABB designs and manufactures turnkey production units for the following coatings and applications:

Architectural paint (construction) and decorative paint (water and solvent)

Industrial paint

Automotive paint, OEMs and recycling

Varnishes and wood coatings

Son heavy duty

Coil coating

Lining

ABB designs and supplies high performance plastics for the production of a wide range of emulsions or water solvents or resins used in the manufacture of paints and varnishes.

In terms of scope and scope of technology, its systems and services, ABB will bring you customized solutions for investment success.

Quantification, treatment and transfer of air by compressed air:

titanium dioxide

Calcium carbonate

talc

silica, aerosil,

barium sulphate, etc.

ABB provides a full range of dispersing and blending units (Dispercel, Delicel) for continuous or batch processes incorporating CIP technology and a new blending tool designed and optimized with flow simulations. . They are specially designed to meet the requirements of paint and coating production: a wide range of products (high solids, viscosity), high abrasion, high pumping speed of viscous products.

batch flexibility, integrated cleaning equipment

Benefit

Fineness of milling: 20 μm for 15 minutes

High speed processing through the turbojet up to 100,000 cps

Improve energy efficiency and increase productivity

Cone for changeable batch size

Accuracy of dosage

Up to 50% cleaning cycle time

Up to 90% of water and solvent used

As part of the optimized factory design, ABB has developed an advanced cleaning system for the coating and coating industries.

In-line filter with integrated cleaning system:

Filter efficiency with reduced pressure reduction

automatic self-healing and self-cleaning

optimal cleaning time

Product losses are low

High efficiency cleaning system for distribution:

High and medium pressure systems

Automatic and repeat cleaning

Use controlled and recycled cleaners

Thanks to the development of components (multi-way valves, manifolds, etc.), tubing technology has become a real process tool making the whole unit more flexible:

Thanks to the development of components (multi-way valves, manifolds, etc.), tubing technology has become a real process tool making the whole unit more flexible:

No cross product pollution

minimum waste discharge

Strong design and low maintenance

attractive return of capital

easy layout and modularity

ABB Paint Experts and Automation Engineers have developed PaintCle, a powerful control system for mass production monitoring and management, fully compliant with the requirements of manufacturers. paint.

Paintcel ensures the full management of materials, product formulas, recipes and recipes, inventory, production and cleaning. Setting parameters allows Paintcel to optimize production.

Paintcel is a factory-wide control system that integrates subsystems such as PLCs, controllers, and MMI. It has no limitation in interfacing with other systems such as laboratories or business systems (ERP).

The planning module of Paintcel allows management of individual unit operations. It integrates the reduction of wastewater, resource management, equipment occupancy and packaging units.

ABB provides a full range of dedicated services to achieve an optimized paint plant operation.

Design and validation, basic techniques, test solutions, process improvement

factory simulation,

Project implementation, detailed research, procurement and construction, site operation, operation and startup

Complete and evolve, train, maintain, evolve and improve the plant

Our engineers will study how to optimize and improve your production performance:, quality at the right price, only in the production of time distribution, direct savings for the production Your paint, count the reaction of your production

Our interest in health and environmental protection has led us to develop initial solutions to: reduce wastewater, reduce volatile organic compounds (VOC), optimize cleaning and Recycle, implement safety procedures and working conditions, work in closed systems

Our interest in health and environmental protection has led us to develop initial solutions to: reduce wastewater, reduce volatile organic compounds (VOC), optimize cleaning and Recycle, implement safety procedures and working conditions, work in closed systems