Thiết bị và công nghệ , sản xuất xi măng – Sweden

Equipment and technology, cement production – Sweden

The cement industry solution for today and tomorrow

High quality cement production, taking care of environmental responsibility

bilities, streamlining the process of controlling and managing information effectively to maintain a reliable, cost-effective and reduced use of capital - what is cement production.

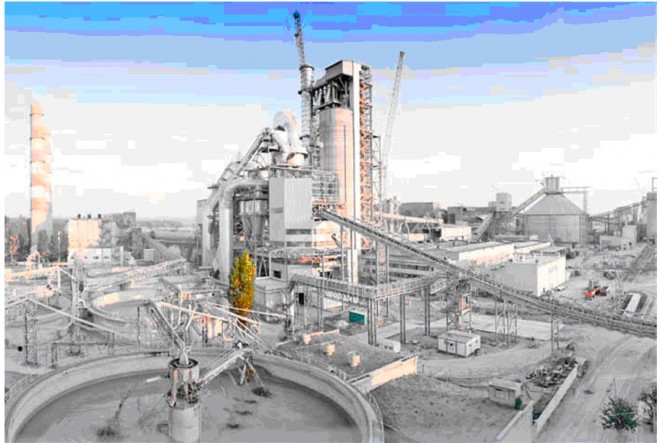

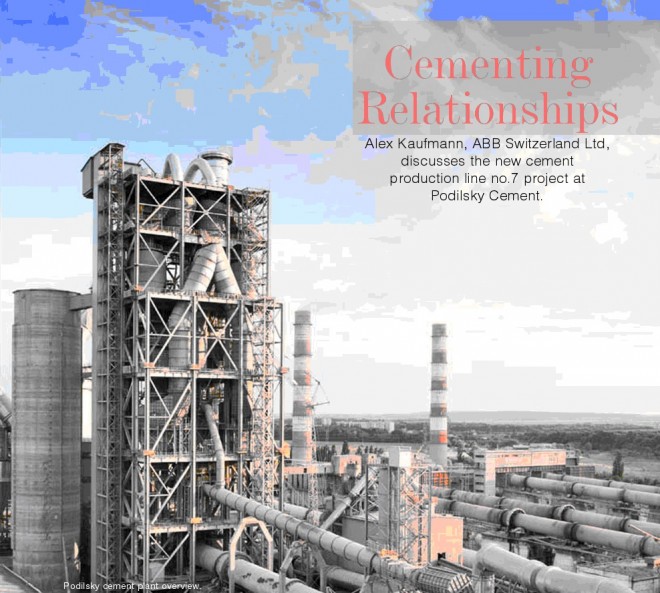

ABB can help you meet these business challenges by providing automation, applications and electrical systems to improve existing plant operation and plant integration processes. Our experience is unprecedented, with a track record of sup- fully electrified cation electrification for more than 150 cement plants worldwide.

Whether you need a single critical component or a complete turnkey electrifi cation, switch to ABB as your sole source.

Energy efficiency

Cement consumed 8.2 exajoules of energy per year, or about 7% of the total amount of industrial fuel used.

Efforts to reduce energy demand, by using higher efficiency equipment and replacing fuel and critical materials to reduce production costs.

These changes introduce constraints that must be managed to ensure the quality and productivity requirements of the plant.

The optimal operating point within the boundaries of the limited fluctuations depends on the reasonable price of the fuel mixture and the timely procurement of the elec- trical energy while continuously reducing the demand for these resources.

The ABB Automation strategy throughout the plant seeks optimal performance points while maximizing product quality and productivity, with the lowest energy consumption and least environmental impact. This is achieved through a

The combination of variable speed drives (VSD), advanced process control,

monitor and report energy.

Power savings of up to 70% can be achieved by using VSD through fixed-speed motors and dampers. The multidrive solution provides a drive solution that is optimized for cooler nets. The control and optimization of the kiln will reduce the heat sumption up to 8 percent. When this is combined with the collec-organization and distribution of production, quality and energy reporting, quick and interactive decisions to reach the goals of energy management are achieved. ABB also offers you an integrated system for the efficient use of waste heat in your plant. The heat that was previously wasted can be transformed into electricity - efficient, economical and CO2 free.

Proven equipment and proven technical solutions ensure energy efficiency without endangering the quality and productivity of a plant cement.

Improve quality

There may be no fault or failure in the cement composition, or the entire structure

can break up Advanced measurement, information and optimization systems are as essential as ever to track and correct any deviation from stand quality - from mine to submitting. ABB's tailor-made products and services improve the process and help you achieve optimum production standards.

Automated system minimizes the use of materials and energy complex processes.

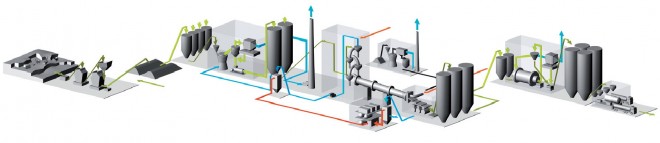

From quarry to port

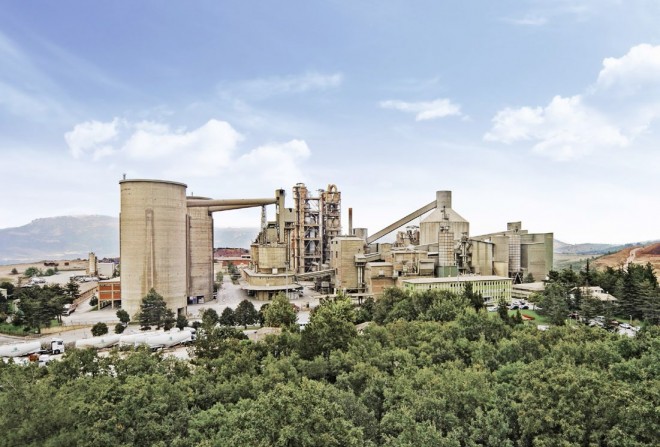

Look beyond ABB. Our approach includes the complete value chain, from your quarry to the product you are selling. We excel at integrating equipment, skills and services to develop a complete, customized solution to enhance your entire operations regardless of the scale of the project. ABB's capabilities, global and local resources, provide integrated power, control and information solutions. You specify the requirements once and we are responsible for creating a smooth and efficient solution.

Power Distribution

When you need efficient and reliable power distribution in cement plants, switch to ABB. We provide the widest range of high, medium and low voltage equipment for converting and distributing electricity to cement plants. The solutions are designed to be safe, flexible and safe to operate day and night, including emergency power and uninterruptible power supply (UPS), industrial substations, and equipment. harmonic adjustment, switches and transformers. ABB provides you with modern technology to reduce the increasingly stringent power demand.

Drive application

Choosing the right drive system for a specific application requires knowledge and experience in the environmental process. ABB produces engines and drives from sub kilowatt to megawatt ratings for cement plants.

As the world's largest manufacturer of variable frequency motors - essential for modern cement production - ABB uses its extensive cement industry expertise to select the best drives to increase throughput, Reliability and energy efficiency in your operation. This ensures that the selected drive system is perfectly suited to the specific requirements of each location.

Control and equipment

Cement plants need to have integrated control systems to improve the efficiency and productivity of the plant. Our information technology process control solutions provide access to process, production, quality and business information easily from the farthest location to the corporate headquarters. . ABB provides tailor-made automation solutions that use real-time data - allowing you to monitor and analyze your processes seamlessly in conjunction with the availability of improved properties whether you are build a greenfield plant or expand or modernize an existing plant.

ABB offers a wide range of products for cement industry processes such as continuous gas analysis systems for process gas measurements, emission monitoring, online measurements for bulk materials, as well as devices for other specific applications. ABB is a global leader with internationally certified solutions and a network of manufacturing plants worldwide.

Collaborative production management solution

ABB's Cement Solutions solution provides the best methods to meet your requirements, goals and objectives including production management solutions. These allow you to drill down into your factory data to whatever level of detail you choose with any key performance metric chosen (KPI). The award optimization solution is optimized for over 400 processes around the world and helps many customers make efficient use of alternative fuels and materials. And solutions for connectivity, allowing complete exchange and viewing of information between all critical business systems.

Service

When it comes to service, we focus on helping your company succeed.

ABB has an extensive network of service centers around the world to support your local facilities. Our field technicians are available day and night to diagnose, repair, upgrade, install or perform onsite maintenance for ABB systems and for many other manufacturers' products. .

Backup maintenance and life support contracts, as well as our training services, help you reduce direct maintenance.

cost, improve operational reliability and increase revenue.

ABB also helps you find the most competitive source of funding to buy the equipment you need.

Electrification and plant technology

The efficiency of an industrial plant is not only affected by large mechanical and electrical equipment. Proper planning and techniques also play an important role.

We ensure the selection of appropriate technology and products, accurate dimensions, compliance with good environmental conditions such as the implementation of dedicated intelligent industry solutions. All of this leads to huge savings in investment and energy consumption adding to a significant increase

the economy of a plant in its life cycle.

Considered as an integrated facility, the plant's infrastructure also includes such items as substation optimization and electrical room layout, cable engineering, grounding systems, detection and protection. fire, air conditioning and ventilation systems, communication systems and much more.

ABB's Electrification Solutions are designed for maximum safety, flexibility, safety and operational availability to keep your plant running day and night.

Fix

Building a new greenfield cement plant is clearly a big commitment,

But the modernization of an old factory to the latest standards, production and level of efficiency while it is still operating, requires a complete set of skills and competencies from the suppliers. and partners.

The challenges faced by each client and factory make each redevelopment project unique by its complexity. It also depends very much on the local conditions, the plant's history, the quality of the local materials and their inherent natural variations. Repairing a cement plant requires an automation and electrification solution that can address these changes in a moment of service announcement and adapt to its "new condition". As effective as possible.

In addition, such a solution can only be successful when the client's partner

And the supplier understands the complexity of the cement production process and has the experience needed to implement this unique solution in a planned downtime. This is where ABB stands out, and stands out as an accepted world - in this area.

Your benefits

Because of ABB's global resources, combined with strong local presence, you can benefit from many advantages. While getting the best technology from anywhere in the world, you can also benefit from complete support through the life cycle of your installation - including engineering, training, operations, translation. and support - throughout the year.

We can help you achieve industry and energy efficiency as well as environmental compliance with products, systems and services that ensure product quality, minimize environmental impact and reduce costs.

Increase productivity and reliability

In addition to improving the quality of clinker, the results of over 170 production lines show an average fuel consumption of 3% and a 5% increase in production. Cement plants require integrated process control systems that use process, drive and distribution information to improve plant efficiency, productivity, and reliability. Trees must manage important business processes and information if they meet management objectives. Accurate and timely information for your employees is critical to achieving higher productivity.

ABB is a leader in providing you with immediate access to essential information. Our advanced cement information management solutions assist you in the field of pro-active decision-making. It allows you to access thousands of data points instantly, when and where it's needed - including business, financial, manufacturing, environmental, technical, and quality information. With a complete access to the plant and the operation of data from a single "window", you can deploy personnel and resources in a decisive and effective way. More transparency allows for effective asset management in the order

to achieve reliable operation.

Environmental safety

Environmental regulations are becoming more and more difficult each year. They become more rigorous, more costly to process, destroy and monitor. ABB technology in environmental measurement and monitoring, process control and optimization, will allow you to increase operational efficiency as well as environment safety.

ABB also helps to safely use waste as a source of energy through combustion. The burning can be placed in the oven or preheater as a plementary fuel sup. This reduces the cost and main fuel consumption.

The experience and expertise of ABB helps cement manufacturers maintain stable combustion conditions while enhancing the use of a wide variety of waste and piping. Working with our customers, we help you reach your goal without wasting fuel.

A comprehensive approach

ABB, dedicated to excellence in cement, develops a specific customer approach. A range of proven automation, drive and power modules will take you from the island to an automated management information system and optimize power and optimize power for lifting. High efficiency of the plant. At ABB, we see your factory and its requirements are a single, fully integrated entity.