Equipment & Technology Manufacturing,Tires,Rubber - Germany

Supply of equipment & technology – Germany

Tire manufacturing tires

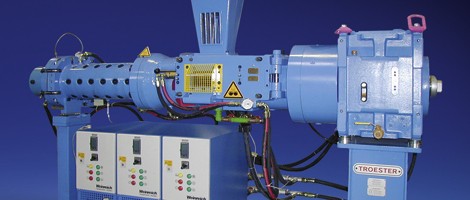

A modern tire may look simple but it is a high-tech product that is undergoing constant development to meet the growing demands of car manufacturers and government organizations. An important element in tire manufacturing is the extrusion of components such as tires, side walls, liners, strips and shafer strips. The final quality of the tire largely depends on the process and this is exactly why the global tire industry relies on the TROESTER extrusion line for this important step in their manufacturing process.

TER has provided hundreds of extrusion line components for tire manufacturers around the world and therefore has extensive experience in processing variants of rubber compounds.

Tire manufacturing tires

A modern tire may look simple but it is a high-tech product that is undergoing constant development to meet the growing demands of car manufacturers and government organizations. An important element in tire manufacturing is the extrusion of components such as tires, side walls, liners, strips and shafer strips. The final quality of the tire largely depends on the process and this is exactly why the global tire industry relies on the TER extrusion line for this important step in their manufacturing process.

TER has provided hundreds of extrusion line components for tire manufacturers around the world and therefore has extensive experience in processing variants of rubber compounds.

Extrusion

The TER rubber screw extruders (GS) manufactured by and used by leading rubber processing companies in Europe and abroad have been recognized as setting quality standards. quantity and quality of products. Extruder GS: right food cooler (GS / k), hot food (GS / w) and vertical extruder (GSV). The GS series also includes a vacuum cleaner (GS Vak) and a battery extruder (QSM).

An extruded QSM extruder is designed similar to conventional extruders. The marked difference lies in the combination of screws and barrels depending on the application, equipped with up to 12 rows of pins.

Nozzles

For many generations, the largest companies in the rubber industry have relied on TER extruders in their processing lines to ensure the quality of their products.

Through decades of design experience, high quality manufacturing and custom personal problem solving means that customers worldwide are guaranteed top quality and output from extruded rubber heads. TER Perfect flow channel design, ensuring the flow of raw materials even in the production process, play a leading role in the implementation of the beginning of the TER.

Wire rolls for the production of technical rubber sheets

The rolls have been used for many years to produce panels for technical rubber products. Typical products include plate products, tank liners, conveyors, V-belts, printing plates, protective pads, pre-press products, soles, pneumatic springs and more. Standard systems are rarely used for production processes; The roller head axes must be specially designed and made according to customer requirements.

Wire Profile and Hose Wire

To produce high quality profiles and tubes, the leading automotive suppliers as well as the medical and construction industry rely on TTER-EXTRUDER, cutting head and vulcanisation.

Our product range includes bath salt, infrared, heater, hot-air shock and microwave units. Modern catalytic converter technology and salt solution without wastewater ensure that the line operation is not worn out.

Shortening and Windup combined with a modern automation system ensure efficient operation.

Continuing research and development helps clients worldwide to stay productive, productive, environmentally safe and secure.

Cross Head TER with hydraulic tool center

Demand for tube production, particularly in the automotive sector, is steadily increasing. In addition to the selection of materials and production processes, the distribution of thickness across the entire diameter of the pipe provides essential quality criteria.

Based on a comprehensive understanding of the production of high quality extruders for the cable industry and years of experience in the production of piping, TER introduces a new system for automatic wall thicknesses. for the production of tubes. The main item of the new system is the crosshead optimized for tube production. The head is supplied by hand by means of conventional manual screws in the front area and additionally allows for a very sensitive rotation with the internal road charge (nail, extrusion) by means of water force. Contrary to well-known solutions, where significant forces are applied hydraulically to external devices (dead pieces), this new design allows for smooth positioning of the axes in radial direction. and with the highest accuracy.

Electrical equipment

The development of new concepts for the extrusion and roll of today

The line always goes with a high degree of automation. De-centralization and fieldbus systems on the machine as well as intranet work of the control line and the IT company, teleservice and internet access are required management to automate the system.

We assure our qualified staff that the rapid innovations in the market for hardware and software components are integrated into the updated solutions for the new control concepts.

Our automation system demonstrates their capabilities every day around the world ensuring high economic efficiency. Line control of TER is always an integral part of a complete solution in our turnkey projects.