The excellent results produced by our injection molding technology together with the optimum control and adjustment systems have made TROESTER a complete line manufacturer and individual machines in the cable industry.

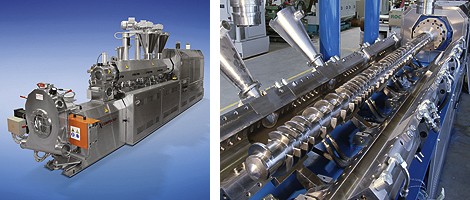

Extrusion

The TROESTER extruder for plastic processing plays an important role throughout the world, especially in the cable industry.

The PX series is used to provide insulation and sheathing of electrical cores, wires and cables; either as a single extrusion machine or an extruded group,

depending on the task at hand. Comprehensive testing in TROESTER's R & D department in conjunction with computer simulations is supported by extensive sputtering test and testing along with composite manufacturers that provide the basis for a dark extrusion machine design. prefer.

The PX extruders are designed according to the latest development of processing technology, there are three different types.

PXA extruder: air-cooled

PXF extruder: liquid cooled design

PXV extrusion machine: vertical design

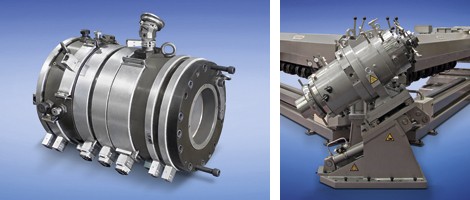

Cross Heads from TROESTER

TROESTER specializes in single, double and triple layer extrusion. It develops and extrudes for all types of lines (such as core insulation, casing, silicon, silicone and CV rubber). Many different types of products can be made with just one head.

The flow channels of all TROESTER extruders are manufactured to extreme accuracy and wall thickness tolerances are closely matched. The result is high quality products made from a minimum of materials. Therefore, TROESTER supports all cable manufacturers who require top-level production efficiency. Streams of computer optimization material also play an important role.

The great effect is that all TROESTER extruders have in common. They also stand out during the very short heating time. Electric heating and liquid temperature control, using the heating / cooling unit, keep the head temperature stable. Quick clamp change setting time to minimum. Easy to clean, save time. TROESTER extrusion provides great flexibility in the production planning process.

> Long service life and low maintenance design

> Large product on each cross head

> Computer line distribution system

> Low tolerance for material saving activities

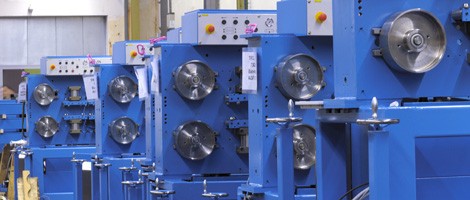

Cable machinery

The planning, design and construction of the cable production line at the request of the customer requires one thing in mind: the experience of exactly what equipment should be selected! This will determine the type of process used and the required technical components.

TROESTER GmbH & Co. KG KG is a complete cable production line provider as well as individual cable machines, such as integrated batteries

or rollers (in static design, portal and floor), rotary caterpillars, belts, capstans and double capstans.

They can be assembled to form a "complete line" when an entire system project is being considered. In addition, they can be used as a single unit to complement an existing line and optimize it from an economic standpoint.

Electrical equipment

As a successful worldwide cable provider from a source, TROESTER offers intelligent control concepts for efficient use of production lines and machinery. TROESTER's know-how in the field of automation, control and measurement technology is self-guided by day-to-day practice and undergoes continuous development.

TROESTER Flow Control demonstrates efficiency and profitability on a daily basis in a large number of production lines around the world. They are always an integral part of a complete line from a company and constitute a guarantee for our customers to operate with state-of-the-art technology.

The factory combines plastic

Since 2011, Swiss X-Compound GmbH belongs to the TROESTER group. It develops and manufactures complete molding systems, pre-installed, easy to install and operate on site (plugs & products). The strength of X-Compound is its excellent experience with various plastic processing technologies that can provide a full range of material distributors and packaging to final packaging and packaging, if desired. Landscaping including building design.

The preferred X-Compound principle for temperature sensitive products is the Einwellenkneter oscillator principle. The advantage of this principle is that the machines easily adapt to the specific needs of the customer as well as high flexibility for future adaptation needs.

X-Compound equipment convinces through individual, individual solutions, high quality of distributed components, easier system operation and high automation.